Page 1172 - The Mechatronics Handbook

P. 1172

REFERENCE

PRESSURE

DISPLACEMENT

SENSOR OUTPUT

WORKING CHAMBER

DIAPHRAGM

INPUT

p

FIGURE 45.7 Diaphragm pressure transducer.

DISPLACEMENT

REFERENCE SENSOR

PRESSURE

∆x

OUTPUT

SPRING

PISTON

WORKING CHAMBER

INPUT

p

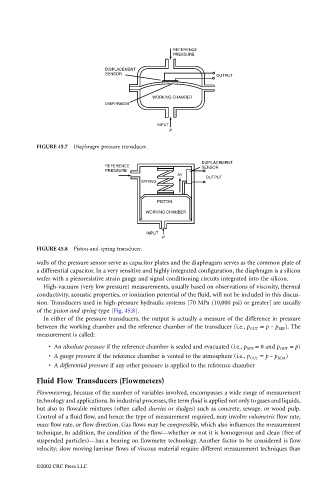

FIGURE 45.8 Piston-and-spring transducer.

walls of the pressure sensor serve as capacitor plates and the diaphragam serves as the common plate of

a differential capacitor. In a very sensitive and highly integrated configuration, the diaphragm is a silicon

wafer with a piezoresistive strain gauge and signal conditioning circuits integrated into the silicon.

High-vacuum (very low pressure) measurements, usually based on observations of viscosity, thermal

conductivity, acoustic properties, or ionization potential of the fluid, will not be included in this discus-

sion. Transducers used in high-pressure hydraulic systems [70 MPa (10,000 psi) or greater] are usually

of the piston and spring type [Fig. 45.8].

In either of the pressure transducers, the output is actually a measure of the difference in pressure

between the working chamber and the reference chamber of the transducer (i.e., p OUT = p - p REF ). The

measurement is called:

•An absolute pressure if the reference chamber is sealed and evacuated (i.e., p REF = 0 and p OUT = p)

•A gauge pressure if the reference chamber is vented to the atmosphere (i.e., p OUT = p - p ATM )

•A differential pressure if any other pressure is applied to the reference chamber

Fluid Flow Transducers (Flowmeters)

Flowmetering, because of the number of variables involved, encompasses a wide range of measurement

technology and applications. In industrial processes, the term fluid is applied not only to gases and liquids,

but also to flowable mixtures (often called slurries or sludges) such as concrete, sewage, or wood pulp.

Control of a fluid flow, and hence the type of measurement required, may involve volumetric flow rate,

mass flow rate, or flow direction. Gas flows may be compressible, which also influences the measurement

technique. In addition, the condition of the flow—whether or not it is homogenous and clean (free of

suspended particles)—has a bearing on flowmeter technology. Another factor to be considered is flow

velocity; slow moving laminar flows of viscous material require different measurement techniques than

©2002 CRC Press LLC