Page 1175 - The Mechatronics Handbook

P. 1175

ULTRASOUND

TRANSMITTER

SOUND PATH

INPUT

FLUID FLOW

ULTRASOUND

RECEIVER

SYNCHRONIZATION

AND TIMING

TIMER OUTPUT

CONVERTER

(a)

PARTICLES

OR BUBBLES

INPUT

FLUID FLOW

TRANSMITTED/

REFLECTED

SOUND PATH

ULTRASOUND

TRANSRECEIVER

FREQUENCY

OUTPUT

SHIFT

(b) CONVERTER

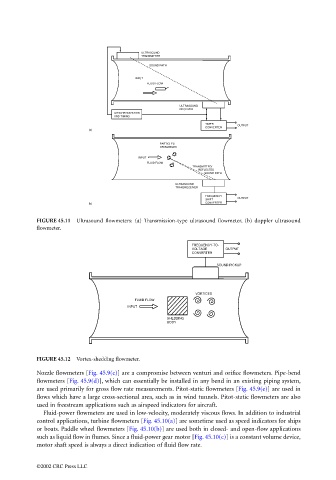

FIGURE 45.11 Ultrasound flowmeters: (a) Transmission-type ultrasound flowmeter, (b) doppler ultrasound

flowmeter.

FREQUENCY-TO-

VOLTAGE OUTPUT

CONVERTER

SOUND PICKUP

VORTICES

FLUID FLOW

INPUT

SHEDDING

BODY

FIGURE 45.12 Vortex-shedding flowmeter.

Nozzle flowmeters [Fig. 45.9(c)] are a compromise between venturi and orifice flowmeters. Pipe-bend

flowmeters [Fig. 45.9(d)], which can essentially be installed in any bend in an existing piping system,

are used primarily for gross flow rate measurements. Pitot-static flowmeters [Fig. 45.9(e)] are used in

flows which have a large cross-sectional area, such as in wind tunnels. Pitot-static flowmeters are also

used in freestream applications such as airspeed indicators for aircraft.

Fluid-power flowmeters are used in low-velocity, moderately viscous flows. In addition to industrial

control applications, turbine flowmeters [Fig. 45.10(a)] are sometime used as speed indicators for ships

or boats. Paddle wheel flowmeters [Fig. 45.10(b)] are used both in closed- and open-flow applications

such as liquid flow in flumes. Since a fluid-power gear motor [Fig. 45.10(c)] is a constant volume device,

motor shaft speed is always a direct indication of fluid flow rate.

©2002 CRC Press LLC