Page 1179 - The Mechatronics Handbook

P. 1179

NON-WETTED

ULTRASOUND

ULTRASOUND OUTPUT ACTUATED

TIMER OUTPUT

SWITCH

TRANSMITTER/

RECEIVER

WETTED TRANSMITTER

ULTRASOUND OUTPUT

TIMER

INPUT INPUT

RECEIVER

LIQUID LIQUID

LEVEL LEVEL

(a) (b)

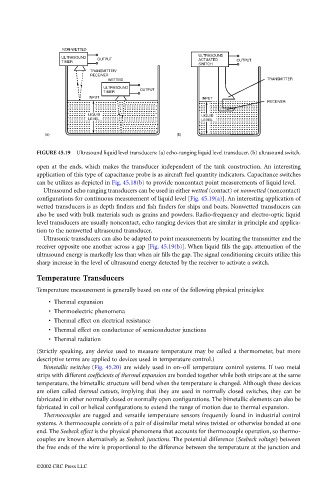

FIGURE 45.19 Ultrasound liquid level transducers: (a) echo-ranging liquid level transducer, (b) ultrasound switch.

open at the ends, which makes the transducer independent of the tank construction. An interesting

application of this type of capacitance probe is as aircraft fuel quantity indicators. Capacitance switches

can be utilizes as depicted in Fig. 45.18(b) to provide noncontact point measurements of liquid level.

Ultrasound echo ranging transducers can be used in either wetted (contact) or nonwetted (noncontact)

configurations for continuous measurement of liquid level [Fig. 45.19(a)]. An interesting application of

wetted transducers is as depth finders and fish finders for ships and boats. Nonwetted transducers can

also be used with bulk materials such as grains and powders. Radio-frequency and electro-optic liquid

level transducers are usually noncontact, echo ranging devices that are similar in principle and applica-

tion to the nonwetted ultrasound transducer.

Ultrasonic transducers can also be adapted to point measurements by locating the transmitter and the

receiver opposite one another across a gap [Fig. 45.19(b)]. When liquid fills the gap, attenuation of the

ultrasound energy is markedly less than when air fills the gap. The signal conditioning circuits utilize this

sharp increase in the level of ultrasound energy detected by the receiver to activate a switch.

Temperature Transducers

Temperature measurement is generally based on one of the following physical principles:

• Thermal expansion

• Thermoelectric phenomena

• Thermal effect on electrical resistance

• Thermal effect on conductance of semiconductor junctions

• Thermal radiation

(Strictly speaking, any device used to measure temperature may be called a thermometer, but more

descriptive terms are applied to devices used in temperature control.)

Bimetallic switches (Fig. 45.20) are widely used in on–off temperature control systems. If two metal

strips with different coefficients of thermal expansion are bonded together while both strips are at the same

temperature, the bimetallic structure will bend when the temperature is changed. Although these devices

are often called thermal cutouts, implying that they are used in normally closed switches, they can be

fabricated in either normally closed or normally open configurations. The bimetallic elements can also be

fabricated in coil or helical configurations to extend the range of motion due to thermal expansion.

Thermocouples are rugged and versatile temperature sensors frequently found in industrial control

systems. A thermocouple consists of a pair of dissimilar metal wires twisted or otherwise bonded at one

end. The Seebeck effect is the physical phenomena that accounts for thermocouple operation, so thermo-

couples are known alternatively as Seebeck junctions. The potential difference (Seebeck voltage) between

the free ends of the wire is proportional to the difference between the temperature at the junction and

©2002 CRC Press LLC