Page 272 - The Mechatronics Handbook

P. 272

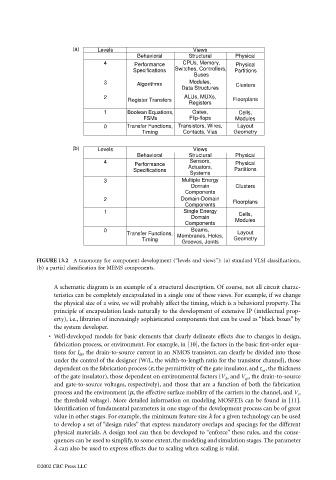

(a) Levels Views

Behavioral Structural Physical

4 Performance CPUs, Memory, Physical

Specifications Switches, Controllers, Partitions

Buses

3 Algorithms Modules, Clusters

Data Structures

2 ALUs, MUXs,

Register Transfers Floorplans

Registers

1 Boolean Equations, Gates, Cells,

FSMs Flip-flops Modules

0 Transfer Functions, Transistors, Wires, Layout

Timing Contacts, Vias Geometry

(b) Levels Views

Behavioral Structural Physical

4 Sensors, Physical

Performance Actuators,

Specifications Partitions

Systems

3 Multiple Energy

Domain Clusters

Components

2 Domain-Domain Floorplans

Components

1 Single Energy Cells,

Domain

Components Modules

0 Beams,

Transfer Functions, Membranes, Holes, Layout

Timing Geometry

Grooves, Joints

FIGURE 13.2 A taxonomy for component development (“levels and views”): (a) standard VLSI classifications,

(b) a partial classification for MEMS components.

A schematic diagram is an example of a structural description. Of course, not all circuit charac-

teristics can be completely encapsulated in a single one of these views. For example, if we change

the physical size of a wire, we will probably affect the timing, which is a behavioral property. The

principle of encapsulation leads naturally to the development of extensive IP (intellectual prop-

erty), i.e., libraries of increasingly sophisticated components that can be used as “black boxes” by

the system developer.

• Well-developed models for basic elements that clearly delineate effects due to changes in design,

fabrication process, or environment. For example, in [10], the factors in the basic first-order equa-

tions for I ds , the drain-to-source current in an NMOS transistor, can clearly be divided into those

under the control of the designer (W/L, the width-to-length ratio for the transistor channel), those

dependent on the fabrication process (ε, the permittivity of the gate insulator, and t ox , the thickness

of the gate insulator), those dependent on environmental factors (V ds and V gs , the drain-to-source

and gate-to-source voltages, respectively), and those that are a function of both the fabrication

process and the environment (µ, the effective surface mobility of the carriers in the channel, and V t ,

the threshold voltage). More detailed information on modeling MOSFETs can be found in [11].

Identification of fundamental parameters in one stage of the development process can be of great

value in other stages. For example, the minimum feature size λ for a given technology can be used

to develop a set of “design rules” that express mandatory overlaps and spacings for the different

physical materials. A design tool can then be developed to “enforce” these rules, and the conse-

quences can be used to simplify, to some extent, the modeling and simulation stages. The parameter

λ can also be used to express effects due to scaling when scaling is valid.

©2002 CRC Press LLC