Page 443 - The Mechatronics Handbook

P. 443

0066_Frame_C19 Page 65 Wednesday, January 9, 2002 5:27 PM

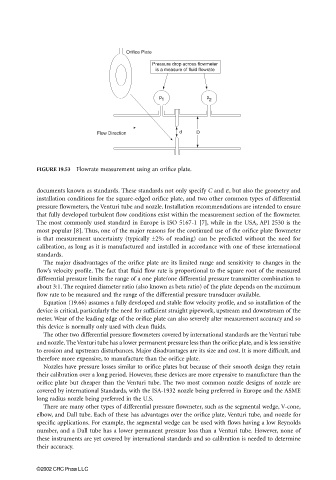

Orifice Plate

Pressure drop across flowmeter

is a measure of fluid flowrate

p p

1 2

Flow Direction d D

FIGURE 19.53 Flowrate measurement using an orifice plate.

documents known as standards. These standards not only specify C and ε, but also the geometry and

installation conditions for the square-edged orifice plate, and two other common types of differential

pressure flowmeters, the Venturi tube and nozzle. Installation recommendations are intended to ensure

that fully developed turbulent flow conditions exist within the measurement section of the flowmeter.

The most commonly used standard in Europe is ISO 5167-1 [7], while in the USA, API 2530 is the

most popular [8]. Thus, one of the major reasons for the continued use of the orifice plate flowmeter

is that measurement uncertainty (typically ±2% of reading) can be predicted without the need for

calibration, as long as it is manufactured and installed in accordance with one of these international

standards.

The major disadvantages of the orifice plate are its limited range and sensitivity to changes in the

flow’s velocity profile. The fact that fluid flow rate is proportional to the square root of the measured

differential pressure limits the range of a one plate/one differential pressure transmitter combination to

about 3:1. The required diameter ratio (also known as beta ratio) of the plate depends on the maximum

flow rate to be measured and the range of the differential pressure transducer available.

Equation (19.66) assumes a fully developed and stable flow velocity profile, and so installation of the

device is critical, particularly the need for sufficient straight pipework, upstream and downstream of the

meter. Wear of the leading edge of the orifice plate can also severely alter measurement accuracy and so

this device is normally only used with clean fluids.

The other two differential pressure flowmeters covered by international standards are the Venturi tube

and nozzle. The Venturi tube has a lower permanent pressure less than the orifice plate, and is less sensitive

to erosion and upstream disturbances. Major disadvantages are its size and cost. It is more difficult, and

therefore more expensive, to manufacture than the orifice plate.

Nozzles have pressure losses similar to orifice plates but because of their smooth design they retain

their calibration over a long period. However, these devices are more expensive to manufacture than the

orifice plate but cheaper than the Venturi tube. The two most common nozzle designs of nozzle are

covered by international Standards, with the ISA-1932 nozzle being preferred in Europe and the ASME

long radius nozzle being preferred in the U.S.

There are many other types of differential pressure flowmeter, such as the segmental wedge, V-cone,

elbow, and Dall tube. Each of these has advantages over the orifice plate, Venturi tube, and nozzle for

specific applications. For example, the segmental wedge can be used with flows having a low Reynolds

number, and a Dall tube has a lower permanent pressure loss than a Venturi tube. However, none of

these instruments are yet covered by international standards and so calibration is needed to determine

their accuracy.

©2002 CRC Press LLC