Page 465 - The Mechatronics Handbook

P. 465

0066_Frame_C19 Page 87 Wednesday, January 9, 2002 5:27 PM

Ti:Saph Laser 76 MHz τ = 200 fs

Solid State Diode Pumped Laser p

λ = 532 nm ~9W λ = 720 nm—880 nm (1.4 eV - 1.7 eV)

Probe Beam 5%

Delay ~ 1500 ps Beam Splitter

λ Plate

/ 2

Sample 20:1

Pump

Dove Prism Lens Beam 95%

1 µs

60

Detector

Polarizer

Variable Acousto-Optic

ND Filter

Modulator @ 1 MHz

Lock-in Amplifier 1 MHz

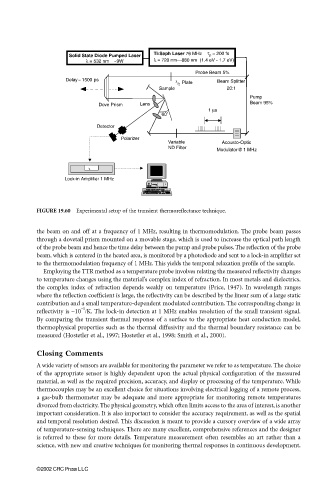

FIGURE 19.60 Experimental setup of the transient thermoreflectance technique.

the beam on and off at a frequency of 1 MHz, resulting in thermomodulation. The probe beam passes

through a dovetail prism mounted on a movable stage, which is used to increase the optical path length

of the probe beam and hence the time delay between the pump and probe pulses. The reflection of the probe

beam, which is centered in the heated area, is monitored by a photodiode and sent to a lock-in amplifier set

to the thermomodulation frequency of 1 MHz. This yields the temporal relaxation profile of the sample.

Employing the TTR method as a temperature probe involves relating the measured reflectivity changes

to temperature changes using the material’s complex index of refraction. In most metals and dielectrics,

the complex index of refraction depends weakly on temperature (Price, 1947). In wavelength ranges

where the reflection coefficient is large, the reflectivity can be described by the linear sum of a large static

contribution and a small temperature-dependent modulated contribution. The corresponding change in

−5

reflectivity is ∼10 /K. The lock-in detection at 1 MHz enables resolution of the small transient signal.

By comparing the transient thermal response of a surface to the appropriate heat conduction model,

thermophysical properties such as the thermal diffusivity and the thermal boundary resistance can be

measured (Hostetler et al., 1997; Hostetler et al., 1998; Smith et al., 2000).

Closing Comments

A wide variety of sensors are available for monitoring the parameter we refer to as temperature. The choice

of the appropriate sensor is highly dependent upon the actual physical configuration of the measured

material, as well as the required precision, accuracy, and display or processing of the temperature. While

thermocouples may be an excellent choice for situations involving electrical logging of a remote process,

a gas-bulb thermometer may be adequate and more appropriate for monitoring remote temperatures

divorced from electricity. The physical geometry, which often limits access to the area of interest, is another

important consideration. It is also important to consider the accuracy requirement, as well as the spatial

and temporal resolution desired. This discussion is meant to provide a cursory overview of a wide array

of temperature-sensing techniques. There are many excellent, comprehensive references and the designer

is referred to these for more details. Temperature measurement often resembles an art rather than a

science, with new and creative techniques for monitoring thermal responses in continuous development.

©2002 CRC Press LLC