Page 115 - Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors

P. 115

88 Thermal Hydraulics Aspects of Liquid Metal Cooled Nuclear Reactors

3.2.3 Gas enhanced circulation

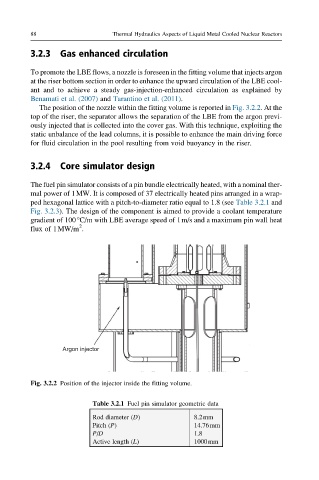

To promote the LBE flows, a nozzle is foreseen in the fitting volume that injects argon

at the riser bottom section in order to enhance the upward circulation of the LBE cool-

ant and to achieve a steady gas-injection-enhanced circulation as explained by

Benamati et al. (2007) and Tarantino et al. (2011).

The position of the nozzle within the fitting volume is reported in Fig. 3.2.2. At the

top of the riser, the separator allows the separation of the LBE from the argon previ-

ously injected that is collected into the cover gas. With this technique, exploiting the

static unbalance of the lead columns, it is possible to enhance the main driving force

for fluid circulation in the pool resulting from void buoyancy in the riser.

3.2.4 Core simulator design

The fuel pin simulator consists of a pin bundle electrically heated, with a nominal ther-

mal power of 1MW. It is composed of 37 electrically heated pins arranged in a wrap-

ped hexagonal lattice with a pitch-to-diameter ratio equal to 1.8 (see Table 3.2.1 and

Fig. 3.2.3). The design of the component is aimed to provide a coolant temperature

gradient of 100°C/m with LBE average speed of 1m/s and a maximum pin wall heat

2

flux of 1MW/m .

Argon injector

Fig. 3.2.2 Position of the injector inside the fitting volume.

Table 3.2.1 Fuel pin simulator geometric data

Rod diameter (D) 8.2mm

Pitch (P) 14.76mm

P/D 1.8

Active length (L) 1000mm