Page 232 - Tribology in Machine Design

P. 232

Sliding-element bearings 217

capacity for wedge action will occur in all the above cases when co/Wj is zero.

For a particular load diagram, use of this fact can be made by plotting oj/a> }

against the crank angle 0 and noting when this value is small compared

with the load W. If this should happen for a comparatively long period

during the load cycle, then a squeeze interval is predominant and squeeze

action theory can be applied as an approximation for the solution of

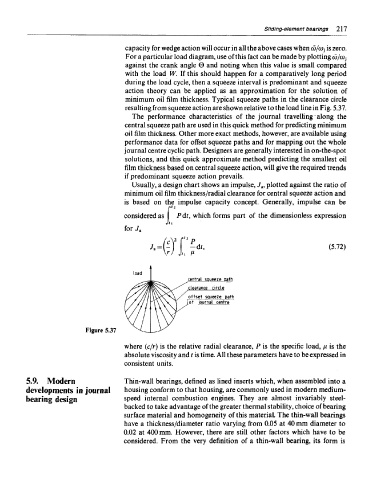

minimum oil film thickness. Typical squeeze paths in the clearance circle

resulting from squeeze action are shown relative to the load line in Fig. 5.37.

The performance characteristics of the journal travelling along the

central squeeze path are used in this quick method for predicting minimum

oil film thickness. Other more exact methods, however, are available using

performance data for offset squeeze paths and for mapping out the whole

journal centre cyclic path. Designers are generally interested in on-the-spot

solutions, and this quick approximate method predicting the smallest oil

film thickness based on central squeeze action, will give the required trends

if predominant squeeze action prevails.

Usually, a design chart shows an impulse, J a, plotted against the ratio of

minimum oil film thickness/radial clearance for central squeeze action and

is based on the impulse capacity concept. Generally, impulse can be

r

considered as Pdt, which forms part of the dimensionless expression

Jfi

for J a

Figure 5.37

where (c/r) is the relative radial clearance, P is the specific load, \JL is the

absolute viscosity and t is time. All these parameters have to be expressed in

consistent units.

5.9. Modern Thin-wall bearings, defined as lined inserts which, when assembled into a

developments in journal housing conform to that housing, are commonly used in modern medium-

bearing design speed internal combustion engines. They are almost invariably steel-

backed to take advantage of the greater thermal stability, choice of bearing

surface material and homogeneity of this material. The thin-wall bearings

have a thickness/diameter ratio varying from 0.05 at 40 mm diameter to

0.02 at 400 mm. However, there are still other factors which have to be

considered. From the very definition of a thin-wall bearing, its form is