Page 183 - Understanding Automotive Electronics

P. 183

2735 | CH 5 Page 170 Tuesday, March 10, 1998 11:10 AM

5 THE BASICS OF ELECTRONIC ENGINE CONTROL

Closed-Loop Control

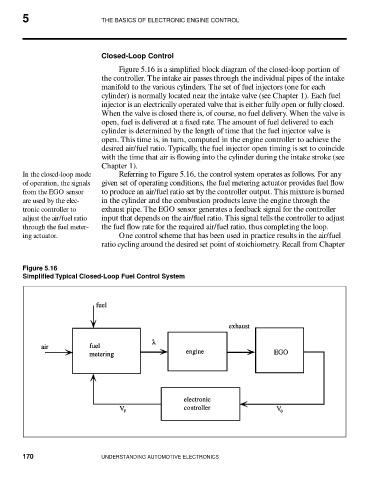

Figure 5.16 is a simplified block diagram of the closed-loop portion of

the controller. The intake air passes through the individual pipes of the intake

manifold to the various cylinders. The set of fuel injectors (one for each

cylinder) is normally located near the intake valve (see Chapter 1). Each fuel

injector is an electrically operated valve that is either fully open or fully closed.

When the valve is closed there is, of course, no fuel delivery. When the valve is

open, fuel is delivered at a fixed rate. The amount of fuel delivered to each

cylinder is determined by the length of time that the fuel injector valve is

open. This time is, in turn, computed in the engine controller to achieve the

desired air/fuel ratio. Typically, the fuel injector open timing is set to coincide

with the time that air is flowing into the cylinder during the intake stroke (see

Chapter 1).

In the closed-loop mode Referring to Figure 5.16, the control system operates as follows. For any

of operation, the signals given set of operating conditions, the fuel metering actuator provides fuel flow

from the EGO sensor to produce an air/fuel ratio set by the controller output. This mixture is burned

are used by the elec- in the cylinder and the combustion products leave the engine through the

tronic controller to exhaust pipe. The EGO sensor generates a feedback signal for the controller

adjust the air/fuel ratio input that depends on the air/fuel ratio. This signal tells the controller to adjust

through the fuel meter- the fuel flow rate for the required air/fuel ratio, thus completing the loop.

ing actuator. One control scheme that has been used in practice results in the air/fuel

ratio cycling around the desired set point of stoichiometry. Recall from Chapter

Figure 5.16

Simplified Typical Closed-Loop Fuel Control System

170 UNDERSTANDING AUTOMOTIVE ELECTRONICS