Page 105 - Valve Selection Handbook

P. 105

92 Valve Selection Handbook

Cylindrical Plug Valves

The use to which plug valves can be put depends to some extent on the

way the seal between the plug and the valve body is produced. In the

case of cylindrical plug valves, four sealing methods are frequently

employed: by a sealing compound, by expanding the plug, by O-rings,

and by wedging an eccentrically shaped plug into the seat.

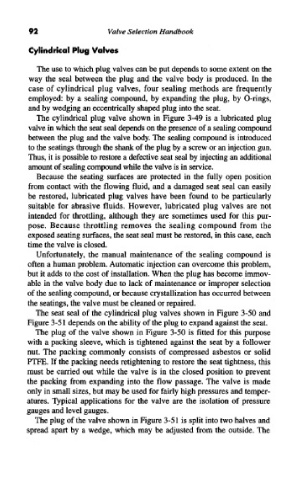

The cylindrical plug valve shown in Figure 3-49 is a lubricated plug

valve in which the seat seal depends on the presence of a sealing compound

between the plug and the valve body. The sealing compound is introduced

to the seatings through the shank of the plug by a screw or an injection gun.

Thus, it is possible to restore a defective seat seal by injecting an additional

amount of sealing compound while the valve is in service.

Because the seating surfaces are protected in the fully open position

from contact with the flowing fluid, and a damaged seat seal can easily

be restored, lubricated plug valves have been found to be particularly

suitable for abrasive fluids. However, lubricated plug valves are not

intended for throttling, although they are sometimes used for this pur-

pose. Because throttling removes the sealing compound from the

exposed seating surfaces, the seat seal must be restored, in this case, each

time the valve is closed.

Unfortunately, the manual maintenance of the sealing compound is

often a human problem. Automatic injection can overcome this problem,

but it adds to the cost of installation. When the plug has become immov-

able in the valve body due to lack of maintenance or improper selection

of the sealing compound, or because crystallization has occurred between

the seatings, the valve must be cleaned or repaired.

The seat seal of the cylindrical plug valves shown in Figure 3-50 and

Figure 3-51 depends on the ability of the plug to expand against the seat.

The plug of the valve shown in Figure 3-50 is fitted for this purpose

with a packing sleeve, which is tightened against the seat by a follower

nut. The packing commonly consists of compressed asbestos or solid

PTFE. If the packing needs retightening to restore the seat tightness, this

must be carried out while the valve is in the closed position to prevent

the packing from expanding into the flow passage. The valve is made

only in small sizes, but may be used for fairly high pressures and temper-

atures. Typical applications for the valve are the isolation of pressure

gauges and level gauges.

The plug of the valve shown in Figure 3-51 is split into two halves and

spread apart by a wedge, which may be adjusted from the outside. The