Page 109 - Valve Selection Handbook

P. 109

96 Valve Selection Handbook

gap between the seatings is therefore relatively wide, so the valve

achieves a satisfactory seat seal only with liquids that have a high surface

tension or viscosity. However, if the plug has been coated with a grease

prior to installation, the valve may be used also for wet gases such as wet

and oily compressed air.

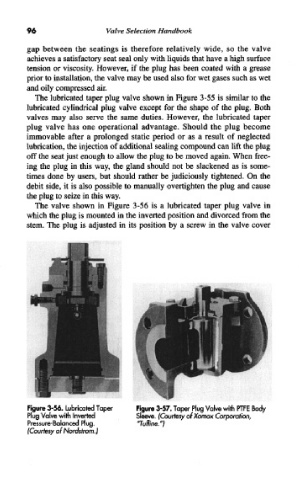

The lubricated taper plug valve shown in Figure 3-55 is similar to the

lubricated cylindrical plug valve except for the shape of the plug. Both

valves may also serve the same duties. However, the lubricated taper

plug valve has one operational advantage. Should the plug become

immovable after a prolonged static period or as a result of neglected

lubrication, the injection of additional sealing compound can lift the plug

off the seat just enough to allow the plug to be moved again. When free-

ing the plug in this way, the gland should not be slackened as is some-

times done by users, but should rather be judiciously tightened. On the

debit side, it is also possible to manually overtighten the plug and cause

the plug to seize in this way.

The valve shown in Figure 3-56 is a lubricated taper plug valve in

which the plug is mounted in the inverted position and divorced from the

stem. The plug is adjusted in its position by a screw in the valve cover

Figure 3-56. Lubricated Taper Figure 3-57. Taper Plug Valve with PTFE Body

Plug Valve with Inverted Sleeve. (Courtesy ofXomox Corporation,

Pressure-Balanced Plug. "Tuttine.")

(Courtesy of Nordstrom.)