Page 107 - Valve Selection Handbook

P. 107

94 Valve Selection Handbook

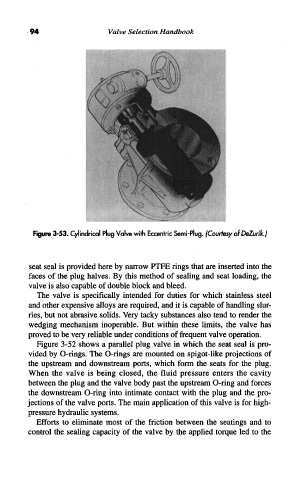

Figure 3-53. Cylindrical Plug Valve with Eccentric Semi-Plug. (Courtesy of DeZurik.)

seat seal is provided here by narrow PTFE rings that are inserted into the

faces of the plug halves. By this method of sealing and seat loading, the

valve is also capable of double block and bleed.

The valve is specifically intended for duties for which stainless steel

and other expensive alloys are required, and it is capable of handling slur-

ries, but not abrasive solids. Very tacky substances also tend to render the

wedging mechanism inoperable. But within these limits, the valve has

proved to be very reliable under conditions of frequent valve operation.

Figure 3-52 shows a parallel plug valve in which the seat seal is pro-

vided by O-rings. The O-rings are mounted on spigot-like projections of

the upstream and downstream ports, which form the seats for the plug.

When the valve is being closed, the fluid pressure enters the cavity

between the plug and the valve body past the upstream O-ring and forces

the downstream O-ring into intimate contact with the plug and the pro-

jections of the valve ports. The main application of this valve is for high-

pressure hydraulic systems.

Efforts to eliminate most of the friction between the seatings and to

control the sealing capacity of the valve by the applied torque led to the