Page 110 - Valve Selection Handbook

P. 110

Manual Valves 97

while the sealant is injected into the body at the stem end. To prevent the

fluid pressure from driving the plug into the seat, the plug ends are pro-

vided with balance holes that permit the fluid pressure to enter the cavi-

ties at both plug ends. By this design the plug valve may be used for very

high pressures without becoming inoperable because of the fluid pressure

driving the plug into the seat.

Efforts to overcome the maintenance problem of lubricated plug

valves led to the development of the taper plug valve shown in Figure 3-

57 in which the plug moves in a PTFE body sleeve. The PTFE body

sleeve keeps the plug from sticking, but the operating torque can still be

relatively high due to the large seating area and the high seating stress.

On the other hand, the large seating area gives good protection against

leakage should some damage occur to the seating surface. As a result, the

valve is rugged and tolerates abusive treatment. The PTFE sleeve also

permits the valve to be made of exotic materials that would otherwise

tend to bind in mutual contact. In addition, the valve is easily repaired in

the field, and no lapping of the plug is required.

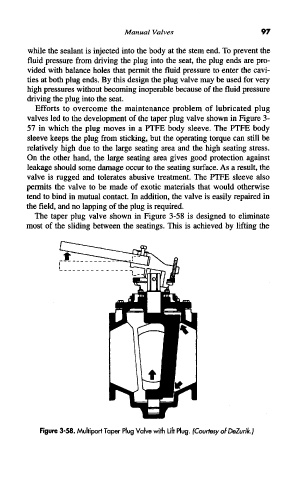

The taper plug valve shown in Figure 3-58 is designed to eliminate

most of the sliding between the seatings. This is achieved by lifting the

Figure 3-58. Multiport Taper Plug Valve with Lift Plug. (Courtesy ofDeZurik.)