Page 129 - Valve Selection Handbook

P. 129

116 Valve Selection Handbook

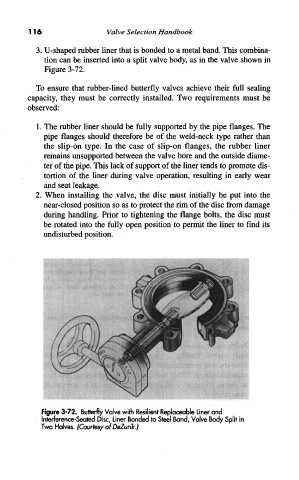

3. U-shaped rubber liner that is bonded to a metal band. This combina-

tion can be inserted into a split valve body, as in the valve shown in

Figure 3-72.

To ensure that rubber-lined butterfly valves achieve their full sealing

capacity, they must be correctly installed. Two requirements must be

observed:

1. The rubber liner should be fully supported by the pipe flanges. The

pipe flanges should therefore be of the weld-neck type rather than

the slip-on type. In the case of slip-on flanges, the rubber liner

remains unsupported between the valve bore and the outside diame-

ter of the pipe. This lack of support of the liner tends to promote dis-

tortion of the liner during valve operation, resulting in early wear

and seat leakage.

2. When installing the valve, the disc must initially be put into the

near-closed position so as to protect the rim of the disc from damage

during handling. Prior to tightening the flange bolts, the disc must

be rotated into the fully open position to permit the liner to find its

undisturbed position.

Figure 3-72. Butterfly Valve with Resilient Replaceable Liner and

Interference-Seated Disc, Liner Bonded to Steel Band, Valve Body Split in

Two Halves. (Courtesy of DeZurik.)