Page 131 - Valve Selection Handbook

P. 131

118 Valve Selection Handbook

Figure 3-73 illustrates the precautions that must be taken when

installing rubber-lined butterfly valves.

The flange of the rubber liner also serves as a sealing element against

the pipeline flanges. The installation of additional rubber gaskets

between pipe flanges and valve would tend to reduce the support of the

rubber liner and, consequently, reduce the sealing capacity of the valve.

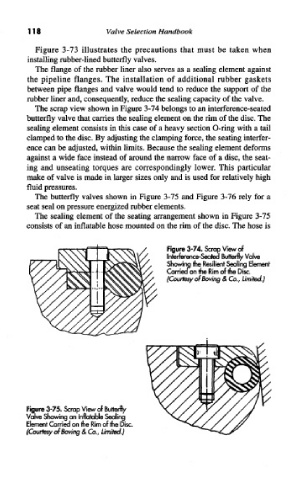

The scrap view shown in Figure 3-74 belongs to an interference-seated

butterfly valve that carries the sealing element on the rim of the disc. The

sealing element consists in this case of a heavy section O-ring with a tail

clamped to the disc. By adjusting the clamping force, the seating interfer-

ence can be adjusted, within limits. Because the sealing element deforms

against a wide face instead of around the narrow face of a disc, the seat-

ing and unseating torques are correspondingly lower. This particular

make of valve is made in larger sizes only and is used for relatively high

fluid pressures.

The butterfly valves shown in Figure 3-75 and Figure 3-76 rely for a

seat seal on pressure energized rubber elements.

The sealing element of the seating arrangement shown in Figure 3-75

consists of an inflatable hose mounted on the rim of the disc. The hose is

/, Figure 3-74. Scrap View of

Interference-Seated Butterfly Valve

Showing the Resilient Sealing Element

Carried on the Rim of the Disc.

(Courtesy of Boving & Co., Limited.)

Figure 3-75. Scrap View of Butterfly

Valve Showing an Inflatable Sealing

Element Carried on the Rim of the Disc.

(Courtesy of Boving & Co., Limited.)