Page 134 - Valve Selection Handbook

P. 134

Manual Valves 121

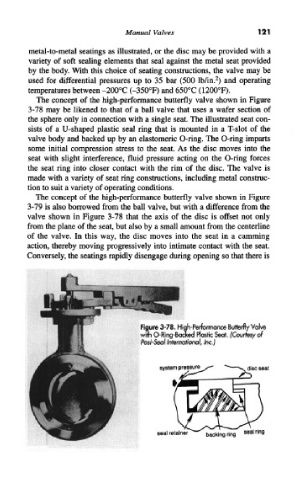

metal-to-metal seatings as illustrated, or the disc may be provided with a

variety of soft sealing elements that seal against the metal seat provided

by the body. With this choice of seating constructions, the valve may be

2

used for differential pressures up to 35 bar (500 lb/in. ) and operating

temperatures between -200°C (-350°F) and 650°C (1200°F).

The concept of the high-performance butterfly valve shown in Figure

3-78 may be likened to that of a ball valve that uses a wafer section of

the sphere only in connection with a single seat. The illustrated seat con-

sists of a U-shaped plastic seal ring that is mounted in a T-slot of the

valve body and backed up by an elastomeric O-ring. The O-ring imparts

some initial compression stress to the seat. As the disc moves into the

seat with slight interference, fluid pressure acting on the O-ring forces

the seat ring into closer contact with the rim of the disc. The valve is

made with a variety of seat ring constructions, including metal construc-

tion to suit a variety of operating conditions.

The concept of the high-performance butterfly valve shown in Figure

3-79 is also borrowed from the ball valve, but with a difference from the

valve shown in Figure 3-78 that the axis of the disc is offset not only

from the plane of the seat, but also by a small amount from the centerline

of the valve. In this way, the disc moves into the seat in a camming

action, thereby moving progressively into intimate contact with the seat.

Conversely, the seatings rapidly disengage during opening so that there is