Page 132 - Valve Selection Handbook

P. 132

Manual Valves 119

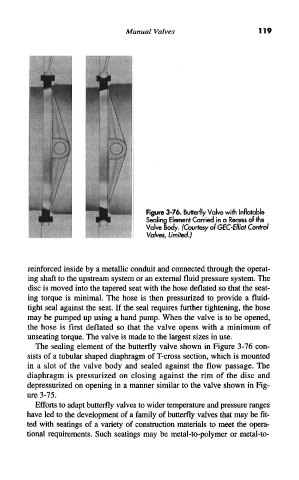

Figure 3-76. Butterfly Valve with Inflatable

Sealing Element Carried in a Recess of the

Valve Body. (Courtesy of GEC-Elliot Control

Valves, Limited.)

reinforced inside by a metallic conduit and connected through the operat-

ing shaft to the upstream system or an external fluid pressure system. The

disc is moved into the tapered seat with the hose deflated so that the seat-

ing torque is minimal. The hose is then pressurized to provide a fluid-

tight seal against the seat. If the seal requires further tightening, the hose

may be pumped up using a hand pump. When the valve is to be opened,

the hose is first deflated so that the valve opens with a minimum of

unseating torque. The valve is made to the largest sizes in use.

The sealing element of the butterfly valve shown in Figure 3-76 con-

sists of a tubular shaped diaphragm of T-cross section, which is mounted

in a slot of the valve body and sealed against the flow passage. The

diaphragm is pressurized on closing against the rim of the disc and

depressurized on opening in a manner similar to the valve shown in Fig-

ure 3-75.

Efforts to adapt butterfly valves to wider temperature and pressure ranges

have led to the development of a family of butterfly valves that may be fit-

ted with seatings of a variety of construction materials to meet the opera-

tional requirements. Such seatings may be metal-to-polymer or metal-to-