Page 133 - Valve Selection Handbook

P. 133

120 Valve Selection Handbook

metal, and may be designed to satisfy the requirements of fire-tested valves.

The majority of these valves may be used for flow in both directions.

Valves of this performance class have acquired the name high-perfor-

mance butterfly valves. The name is taken to mean that this type of but-

terfly valve has a greater pressure-temperature envelope than the com-

mon elastomer-lined or seated butterfly valves. Figure 3-77 through

Figure 3-83 show examples of such valves. However, the illustrations do

not show all the seal variations available for each particular valve.

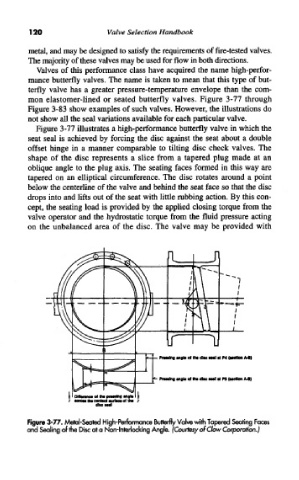

Figure 3-77 illustrates a high-performance butterfly valve in which the

seat seal is achieved by forcing the disc against the seat about a double

offset hinge in a manner comparable to tilting disc check valves. The

shape of the disc represents a slice from a tapered plug made at an

oblique angle to the plug axis. The seating faces formed in this way are

tapered on an elliptical circumference. The disc rotates around a point

below the centerline of the valve and behind the seat face so that the disc

drops into and lifts out of the seat with little rubbing action. By this con-

cept, the seating load is provided by the applied closing torque from the

valve operator and the hydrostatic torque from the fluid pressure acting

on the unbalanced area of the disc. The valve may be provided with

Figure 3-77. Metal-Seated High-Performance Butterfly Valve with Tapered Seating Faces

and Sealing of the Disc at a Non-Interlocking Angle. (Courtesy of Clow Corporation.)