Page 266 - Valve Selection Handbook

P. 266

Rupture Discs 253

Figure 6-35. Explosion Vent Panel of

Composite Construction Before and After

Bursting. (Courtesy of Continental Disc

Corporation.)

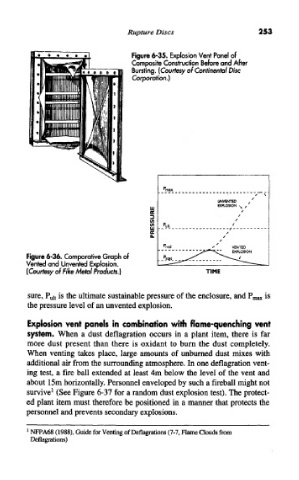

Figure 6-36. Comparative Graph of

Vented and Unvented Explosion.

{Courtesy ofFike Metal Products.)

sure, P uU is the ultimate sustainable pressure of the enclosure, and P max is

the pressure level of an unvented explosion.

Explosion vent panels in combination with flame-quenching vent

system. When a dust deflagration occurs in a plant item, there is far

more dust present than there is oxidant to burn the dust completely.

When venting takes place, large amounts of unburned dust mixes with

additional air from the surrounding atmosphere. In one deflagration vent-

ing test, a fire ball extended at least 4m below the level of the vent and

about 15m horizontally. Personnel enveloped by such a fireball might not

survive 1 (See Figure 6-37 for a random dust explosion test). The protect-

ed plant item must therefore be positioned in a manner that protects the

personnel and prevents secondary explosions.

1

NFPA68 (1988), Guide for Venting of Deflagrations (7-7, Flame Clouds from

Deflagrations)