Page 161 - Materials Chemistry, Second Edition

P. 161

CAT3525_C06.qxd 1/29/2005 9:56 AM Page 132

132 Waste Management Practices: Municipal, Hazardous, and Industrial

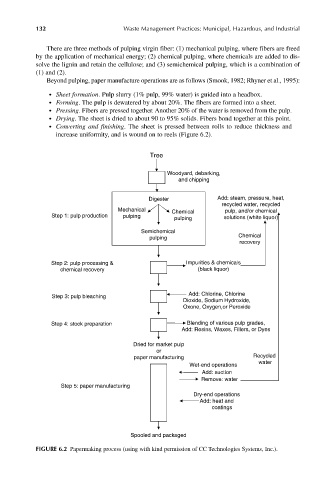

There are three methods of pulping virgin fiber: (1) mechanical pulping, where fibers are freed

by the application of mechanical energy; (2) chemical pulping, where chemicals are added to dis-

solve the lignin and retain the cellulose; and (3) semichemical pulping, which is a combination of

(1) and (2).

Beyond pulping, paper manufacture operations are as follows (Smook, 1982; Rhyner et al., 1995):

● Sheet formation. Pulp slurry (1% pulp, 99% water) is guided into a headbox.

● Forming. The pulp is dewatered by about 20%. The fibers are formed into a sheet.

● Pressing. Fibers are pressed together. Another 20% of the water is removed from the pulp.

● Drying. The sheet is dried to about 90 to 95% solids. Fibers bond together at this point.

● Converting and finishing. The sheet is pressed between rolls to reduce thickness and

increase uniformity, and is wound on to reels (Figure 6.2).

Tree

Woodyard, debarking,

and chipping

Digester Add: steam, pressure, heat,

recycled water, recycled

Mechanical Chemical pulp, and/or chemical

Step 1: pulp production pulping pulping solutions (white liquor)

Semichemical

pulping Chemical

recovery

Step 2: pulp processing & Impurities & chemicals

chemical recovery (black liquor)

Add: Chlorine, Chlorine

Step 3: pulp bleaching

Dioxide, Sodium Hydroxide,

Oxone, Oxygen,or Peroxide

Step 4: stock preparation Blending of various pulp grades,

Add: Resins, Waxes, Fillers, or Dyes

Dried for market pulp

or

paper manufacturing Recycled

water

Wet-end operations

Add: suction

Remove: water

Step 5: paper manufacturing

Dry-end operations

Add: heat and

coatings

Spooled and packaged

FIGURE 6.2 Papermaking process (using with kind permission of CC Technologies Systems, Inc.).