Page 254 - Materials Chemistry, Second Edition

P. 254

CAT3525_C08.qxd 1/29/2005 10:03 AM Page 225

Composting MSW 225

Pile-turning equipment determines the size, shape, and space between the windrows. Front-end

loaders are commonly used in smaller operations. Windrow turners, also known as scarab com-

posters, straddle windrows and thoroughly mix materials as it moves over the pile. These machines

are either self-propelled or mounted to front-end loaders (Figure 8.6). Self-propelled windrow turn-

ers minimize the required space between windrows.

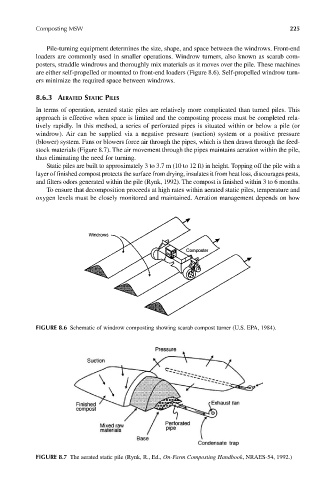

8.6.3 AERATED STATIC PILES

In terms of operation, aerated static piles are relatively more complicated than turned piles. This

approach is effective when space is limited and the composting process must be completed rela-

tively rapidly. In this method, a series of perforated pipes is situated within or below a pile (or

windrow). Air can be supplied via a negative pressure (suction) system or a positive pressure

(blower) system. Fans or blowers force air through the pipes, which is then drawn through the feed-

stock materials (Figure 8.7). The air movement through the pipes maintains aeration within the pile,

thus eliminating the need for turning.

Static piles are built to approximately 3 to 3.7 m (10 to 12 ft) in height. Topping off the pile with a

layer of finished compost protects the surface from drying, insulates it from heat loss, discourages pests,

and filters odors generated within the pile (Rynk, 1992). The compost is finished within 3 to 6 months.

To ensure that decomposition proceeds at high rates within aerated static piles, temperature and

oxygen levels must be closely monitored and maintained. Aeration management depends on how

FIGURE 8.6 Schematic of windrow composting showing scarab compost turner (U.S. EPA, 1984).

FIGURE 8.7 The aerated static pile (Rynk, R., Ed., On-Farm Composting Handbook, NRAES-54, 1992.)