Page 255 - Materials Chemistry, Second Edition

P. 255

CAT3525_C08.qxd 1/29/2005 10:03 AM Page 226

226 Waste Management Practices: Municipal, Hazardous, and Industrial

the blower is controlled. The blower can be run continuously or intermittently. Continuous opera-

tion permits lower airflow rates because oxygen and cooling are supplied constantly. Intermittent

operation of the blower is achieved with a timer or temperature feedback system.

8.6.4 IN-VESSEL SYSTEMS

In-vessel systems are relatively sophisticated units in which composting is conducted within a fully

enclosed chamber. Environmental conditions are mechanically controlled and usually automated.

An in-vessel system may be suitable for MSW composting if:

● The process must be finished rapidly

● Odor and leachate control are a significant concern

● Space is limited

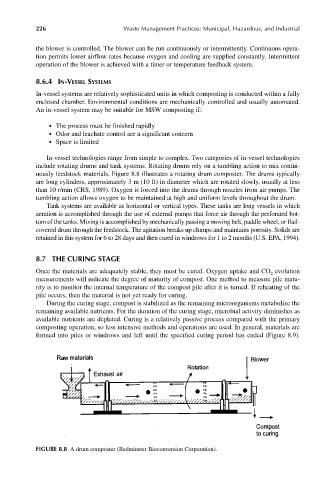

In-vessel technologies range from simple to complex. Two categories of in-vessel technologies

include rotating drums and tank systems. Rotating drums rely on a tumbling action to mix contin-

uously feedstock materials. Figure 8.8 illustrates a rotating drum composter. The drums typically

are long cylinders, approximately 3 m (10 ft) in diameter which are rotated slowly, usually at less

than 10 r/min (CRS, 1989). Oxygen is forced into the drums through nozzles from air pumps. The

tumbling action allows oxygen to be maintained at high and uniform levels throughout the drum.

Tank systems are available as horizontal or vertical types. These tanks are long vessels in which

aeration is accomplished through the use of external pumps that force air through the perforated bot-

tom of the tanks. Mixing is accomplished by mechanically passing a moving belt, paddle wheel, or flail-

covered drum through the feedstock. The agitation breaks up clumps and maintains porosity. Solids are

retained in this system for 6 to 28 days and then cured in windrows for 1 to 2 months (U.S. EPA, 1994).

8.7 THE CURING STAGE

Once the materials are adequately stable, they must be cured. Oxygen uptake and CO evolution

2

measurements will indicate the degree of maturity of compost. One method to measure pile matu-

rity is to monitor the internal temperature of the compost pile after it is turned. If reheating of the

pile occurs, then the material is not yet ready for curing.

During the curing stage, compost is stabilized as the remaining microorganisms metabolize the

remaining available nutrients. For the duration of the curing stage, microbial activity diminishes as

available nutrients are depleted. Curing is a relatively passive process compared with the primary

composting operation, so less intensive methods and operations are used. In general, materials are

formed into piles or windrows and left until the specified curing period has ended (Figure 8.9).

FIGURE 8.8 A drum composter (Bedminster Bioconversion Corporation).