Page 536 - Materials Chemistry, Second Edition

P. 536

CAT3525_C16.qxd 1/27/2005 12:42 PM Page 507

Hazardous Waste Treatment 507

It is important to conduct a waste characterization early in the design of a waste neutralization

process. The overall chemical composition of the waste, including variations in strength, must be

known to ensure the correct design of the treatment system. Similarly, the waste flow rate will affect

the size of the treatment system. Waste characterization is a requirement for hazardous waste genera-

tors (see Chapter 12) and can be accomplished using established laboratory procedures or by consid-

ering the nature of the facility’s processes. Waste strength (i.e., concentration of acidity or alkalinity)

is determined by collecting representative samples of the waste and performing a simple titration.

Depending on waste properties, pretreatment may be necessary prior to neutralization.

Pretreatment can include filtration, sedimentation, and equalization. Other common pretreatment

steps include cyanide destruction, chromium reduction, and removal of oil and grease.

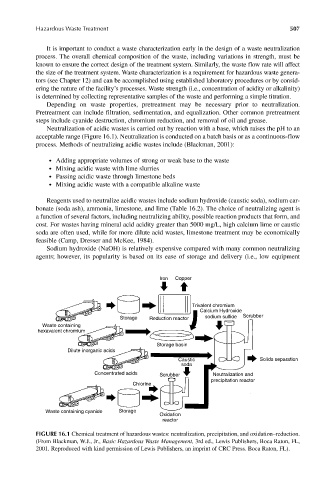

Neutralization of acidic wastes is carried out by reaction with a base, which raises the pH to an

acceptable range (Figure 16.1). Neutralization is conducted on a batch basis or as a continuous-flow

process. Methods of neutralizing acidic wastes include (Blackman, 2001):

● Adding appropriate volumes of strong or weak base to the waste

● Mixing acidic waste with lime slurries

● Passing acidic waste through limestone beds

● Mixing acidic waste with a compatible alkaline waste

Reagents used to neutralize acidic wastes include sodium hydroxide (caustic soda), sodium car-

bonate (soda ash), ammonia, limestone, and lime (Table 16.2). The choice of neutralizing agent is

a function of several factors, including neutralizing ability, possible reaction products that form, and

cost. For wastes having mineral acid acidity greater than 5000 mg/L, high calcium lime or caustic

soda are often used, while for more dilute acid wastes, limestone treatment may be economically

feasible (Camp, Dresser and McKee, 1984).

Sodium hydroxide (NaOH) is relatively expensive compared with many common neutralizing

agents; however, its popularity is based on its ease of storage and delivery (i.e., low equipment

Iron Copper

Trivalent chromium

Calcium Hydroxide

Storage Reduction reactor sodium sulfide Scrubber

Waste containing

hexavalent chromium

Storage basin

Dilute inorganic acids

Caustic Solids separation

soda

Concentrated acids Scrubber Neutralization and

precipitation reactor

Chlorine

Waste containing cyanide Storage

Oxidation

reactor

FIGURE 16.1 Chemical treatment of hazardous wastes: neutralization, precipitation, and oxidation–reduction.

(From Blackman, W.J., Jr., Basic Hazardous Waste Management, 3rd ed., Lewis Publishers, Boca Raton, FL,

2001. Reproduced with kind permission of Lewis Publishers, an imprint of CRC Press. Boca Raton, FL).