Page 121 - Water and wastewater engineering

P. 121

3-18 WATER AND WASTEWATER ENGINEERING

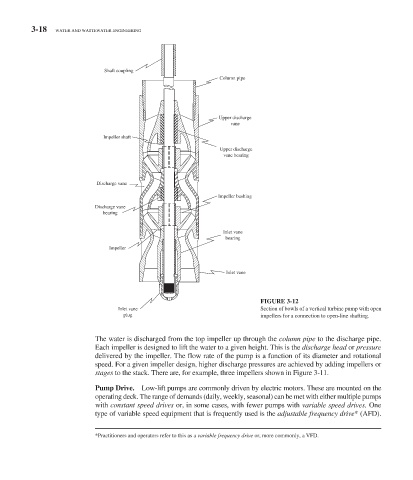

Shaft coupling

Column pipe

Upper discharge

vane

Impeller shaft

Upper discharge

vane bearing

Discharge vane

Impeller bushing

Discharge vane

bearing

Inlet vane

bearing

Impeller

Inlet vane

FIGURE 3-12

Inlet vane Section of bowls of a vertical turbine pump with open

plug impellers for a connection to open-line shafting.

The water is discharged from the top impeller up through the column pipe to the discharge pipe.

Each impeller is designed to lift the water to a given height. This is the discharge head or pressure

delivered by the impeller. The flow rate of the pump is a function of its diameter and rotational

speed. For a given impeller design, higher discharge pressures are achieved by adding impellers or

stages to the stack. There are, for example, three impellers shown in Figure 3-11 .

Pump Drive. Low-lift pumps are commonly driven by electric motors. These are mounted on the

operating deck. The range of demands (daily, weekly, seasonal) can be met with either multiple pumps

with constant speed drives or, in some cases, with fewer pumps with variable speed drives. One

type of variable speed equipment that is frequently used is the adjustable frequency drive * (AFD).

* Practitioners and operators refer to this as a variable frequency drive or, more commonly, a VFD.