Page 137 - Water and wastewater engineering

P. 137

3-34 WATER AND WASTEWATER ENGINEERING

Physical barrier screens are the most widely accepted and successful approach. The screens

are fine mesh with openings of 1.75 mm. The inlet velocity is designed to be a maximum of 12

cm/s (Foellmi, 2005).

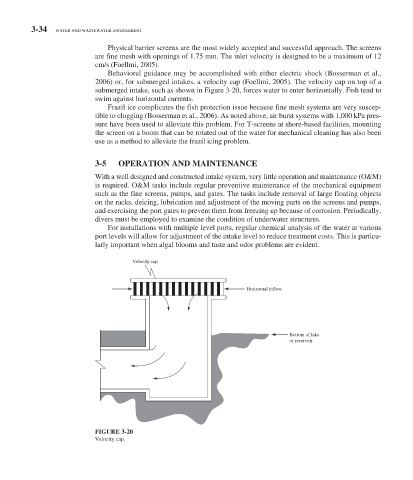

Behavioral guidance may be accomplished with either electric shock (Bosserman et al.,

2006) or, for submerged intakes, a velocity cap (Foellmi, 2005). The velocity cap on top of a

submerged intake, such as shown in Figure 3-20 , forces water to enter horizontally. Fish tend to

swim against horizontal currents.

Frazil ice complicates the fish protection issue because fine mesh systems are very suscep-

tible to clogging (Bosserman et al., 2006). As noted above, air burst systems with 1,000 kPa pres-

sure have been used to alleviate this problem. For T-screens at shore-based facilities, mounting

the screen on a boom that can be rotated out of the water for mechanical cleaning has also been

use as a method to alleviate the frazil icing problem.

3-5 OPERATION AND MAINTENANCE

With a well designed and constructed intake system, very little operation and maintenance (O&M)

is required. O&M tasks include regular preventive maintenance of the mechanical equipment

such as the fine screens, pumps, and gates. The tasks include removal of large floating objects

on the racks, deicing, lubrication and adjustment of the moving parts on the screens and pumps,

and exercising the port gates to prevent them from freezing up because of corrosion. Periodically,

divers must be employed to examine the condition of underwater structures.

For installations with multiple level ports, regular chemical analysis of the water at various

port levels will allow for adjustment of the intake level to reduce treatment costs. This is particu-

larly important when algal blooms and taste and odor problems are evident.

Velocity cap

Horizontal inflow

Bottom of lake

or reservoir

FIGURE 3-20

Velocity cap.