Page 154 - Water and wastewater engineering

P. 154

WELLS 4-9

Pump

Mixer

Grout overflow Grout

Top soil

Grout pipe

Drilled hole

diameter at

Steel casing

least 5 cm

larger than

well casing

Well casing Non-caving

Rubber seat

formation

(clay)

Plastic ball valve

Casing filled

Plastic cage

with water or

mud fluid

Concrete

Grout

Fractured

bedrock

Pipe off

the bottom

(a) (b)

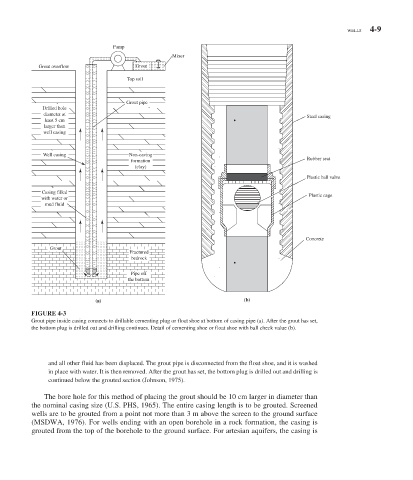

FIGURE 4-3

Grout pipe inside casing connects to drillable cementing plug or float shoe at bottom of casing pipe (a). After the grout has set,

the bottom plug is drilled out and drilling continues. Detail of cementing shoe or float shoe with ball check value (b).

and all other fluid has been displaced. The grout pipe is disconnected from the float shoe, and it is washed

in place with water. It is then removed. After the grout has set, the bottom plug is drilled out and drilling is

continued below the grouted section (Johnson, 1975).

The bore hole for this method of placing the grout should be 10 cm larger in diameter than

the nominal casing size (U.S. PHS, 1965). The entire casing length is to be grouted. Screened

wells are to be grouted from a point not more than 3 m above the screen to the ground surface

(MSDWA, 1976). For wells ending with an open borehole in a rock formation, the casing is

grouted from the top of the borehole to the ground surface. For artesian aquifers, the casing is