Page 157 - Water and wastewater engineering

P. 157

4-12 WATER AND WASTEWATER ENGINEERING

Both gravel-packed wells and those in consolidated formations benefit from well development

because the placement of the rock and the drilling operations tend to smear and seal the surface

of the aquifer material around the well. The development operations will break up this layer. This

effort is worthwhile to obtain the maximum capacity of the well.

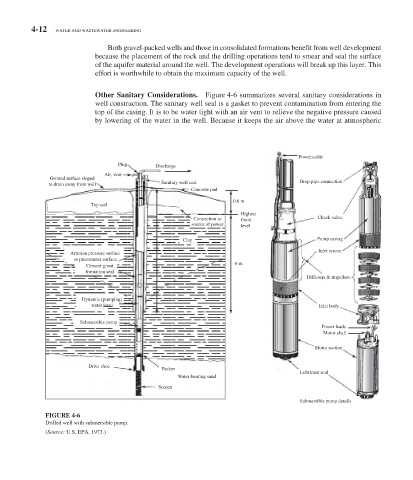

Other Sanitary Considerations. Figure 4-6 summarizes several sanitary considerations in

well construction. The sanitary well seal is a gasket to prevent contamination from entering the

top of the casing. It is to be water tight with an air vent to relieve the negative pressure caused

by lowering of the water in the well. Because it keeps the air above the water at atmospheric

Power cable

Plug Discharge

Air, vent

Ground surface sloped

to drain away from well Sanitary well seal Drop pipe connection

Concrete pad

0.6 m

Top soil

Highest

Connection to flood Check valve

source of power

level

Clay Pump casing

Inlet screen

Artesian pressure surface

or piezometer surface

6 m

Cement grout

formation seal

Diffusers & impellers

Dynamic (pumping)

water level Inlet body

Submersible pump

Power leads

Motor shaft

Motor section

Drive shoe

Packer

Lubricant seal

Water-bearing sand

Screen

Submersible pump details

FIGURE 4-6

Drilled well with submersible pump.

( Source: U.S. EPA, 1973.)