Page 405 - Water and wastewater engineering

P. 405

10-22 WATER AND WASTEWATER ENGINEERING

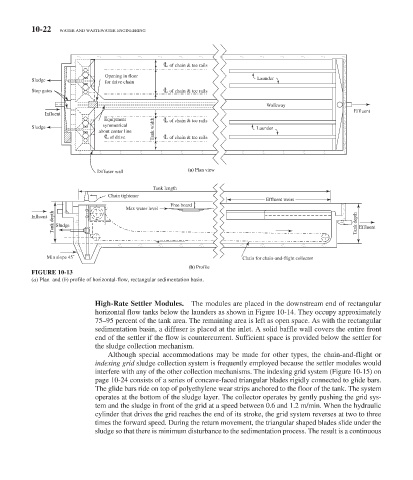

C L of chain & tee rails

Opening in floor

Sludge Launder

for drive chain

Stop gates C L of chain & tee rails

Walkway

Effluent

Influent

Equipment C L of chain & tee rails

symmetrical

Sludge Launder

about center line Tank width

C L C L of chain & tee rails

of drive

Diffuser wall (a) Plan view

Tank length

Chain tightener

Effluent weirs

Free board

Max water level

Tank depth Sludge Tank depth Effluent

Influent

Min slope 45 ° Chain for chain-and-flight collector

(b) Profile

FIGURE 10-13

( a ) Plan and ( b ) profile of horizontal-flow, rectangular sedimentation basin.

High-Rate Settler Modules. The modules are placed in the downstream end of rectangular

horizontal flow tanks below the launders as shown in Figure 10-14 . They occupy approximately

75–95 percent of the tank area. The remaining area is left as open space. As with the rectangular

sedimentation basin, a diffuser is placed at the inlet. A solid baffle wall covers the entire front

end of the settler if the flow is countercurrent. Sufficient space is provided below the settler for

the sludge collection mechanism.

Although special accommodations may be made for other types, the chain-and-flight or

indexing grid sludge collection system is frequently employed because the settler modules would

interfere with any of the other collection mechanisms. The indexing grid system ( Figure 10-15 ) on

page 10-24 consists of a series of concave-faced triangular blades rigidly connected to glide bars.

The glide bars ride on top of polyethylene wear strips anchored to the floor of the tank. The system

operates at the bottom of the sludge layer. The collector operates by gently pushing the grid sys-

tem and the sludge in front of the grid at a speed between 0.6 and 1.2 m/min. When the hydraulic

cylinder that drives the grid reaches the end of its stroke, the grid system reverses at two to three

times the forward speed. During the return movement, the triangular shaped blades slide under the

sludge so that there is minimum disturbance to the sedimentation process. The result is a continuous