Page 410 - Water and wastewater engineering

P. 410

SEDIMENTATION 10-27

5

Recommended values for the settling zone design are R < 20,000 and Fr > 10 (Kawamura,

2000). A large Reynolds number indicates a high degree of turbulence. A low Froude number

indicates that water flow is not dominated by horizontal flow, and backmixing may occur. Like

all design criteria, these values are based on experience. While the desired Reynolds number is

relatively easy to achieve by modifying the tank shape, the recommended Froude number is very

sensitive to the shape of the tank and is difficult to achieve while maintaining other design crite-

3

ria when the flow rates are under 40,000 m /d.

The Reynolds number may be reduced and the Froude number increased by the placement of

baffles parallel to the direction of flow. The baffles must be placed above the sludge collection

equipment and should be about 3 m apart (MWH, 2005).

GLUMRB (2003) recommends a minimum of four hours detention time or an overflow rate

not to exceed 1.2 m/h. This appears to be a carryover from the time when basins were manually

cleaned and were designed with depths of 5 m or more to store large volumes of sludge between

cleaning. Thus, more than half the volume could be filled with sludge before cleaning was re-

quired, and real detention times could vary from four hours when the tank was clean to less than

two hours just before cleaning. Modern designs do not provide for this large of a storage zone,

and detention times of 1.5 to 2.0 h have proven to provide excellent treatment (Willis, 2005).

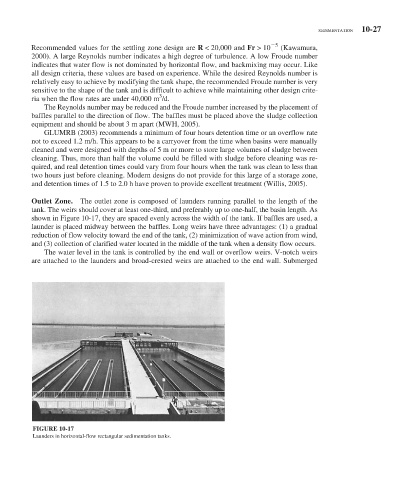

Outlet Zone. The outlet zone is composed of launders running parallel to the length of the

tank. The weirs should cover at least one-third, and preferably up to one-half, the basin length. As

shown in Figure 10-17 , they are spaced evenly across the width of the tank. If baffles are used, a

launder is placed midway between the baffles. Long weirs have three advantages: (1) a gradual

reduction of flow velocity toward the end of the tank, (2) minimization of wave action from wind,

and (3) collection of clarified water located in the middle of the tank when a density flow occurs.

The water level in the tank is controlled by the end wall or overflow weirs. V-notch weirs

are attached to the launders and broad-crested weirs are attached to the end wall. Submerged

FIGURE 10-17

Launders in horizontal-flow rectangular sedimentation tanks.