Page 497 - Water and wastewater engineering

P. 497

12-14 WATER AND WASTEWATER ENGINEERING

Chlorine

solution

reservoir

Calibration

column

Positive

displacement Backwash

pump pump

Flow Backwash

P1 P1

meter valve

Water FM

supply Feed Filtrate

Feed Strainer valve valve

pump Feed Membrane Filtrate

Backwash sample modules sample

discharge point point

Distribution

Filtered

water

reservoir

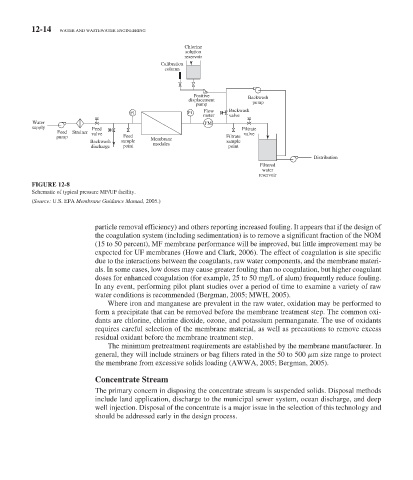

FIGURE 12-8

Schematic of typical pressure MF/UF facility.

( Source: U.S. EPA Membrane Guidance Manual, 2005.)

particle removal efficiency) and others reporting increased fouling. It appears that if the design of

the coagulation system (including sedimentation) is to remove a significant fraction of the NOM

(15 to 50 percent), MF membrane performance will be improved, but little improvement may be

expected for UF membranes (Howe and Clark, 2006). The effect of coagulation is site specific

due to the interactions between the coagulants, raw water components, and the membrane materi-

als. In some cases, low doses may cause greater fouling than no coagulation, but higher coagulant

doses for enhanced coagulation (for example, 25 to 50 mg/L of alum) frequently reduce fouling.

In any event, performing pilot plant studies over a period of time to examine a variety of raw

water conditions is recommended (Bergman, 2005; MWH, 2005).

Where iron and manganese are prevalent in the raw water, oxidation may be performed to

form a precipitate that can be removed before the membrane treatment step. The common oxi-

dants are chlorine, chlorine dioxide, ozone, and potassium permanganate. The use of oxidants

requires careful selection of the membrane material, as well as precautions to remove excess

residual oxidant before the membrane treatment step.

The minimum pretreatment requirements are established by the membrane manufacturer. In

general, they will include strainers or bag filters rated in the 50 to 500 m size range to protect

the membrane from excessive solids loading (AWWA, 2005; Bergman, 2005).

Concentrate Stream

The primary concern in disposing the concentrate stream is suspended solids. Disposal methods

include land application, discharge to the municipal sewer system, ocean discharge, and deep

well injection. Disposal of the concentrate is a major issue in the selection of this technology and

should be addressed early in the design process.