Page 92 - Welding Robots Technology, System Issues, and Applications

P. 92

Welding Robots

78

sensors must be applied. The most common use of sensors are (i) optical sensors

that use a laser light source on the weld joint under study and a sensor with a

narrow bandwidth filter to extract the information of interest, and (ii) through-arc

sensing that uses the electrical parameters from the arc together with knowledge

about the motion of the weld torch which is controlled by the robot.

3.2.1 Optical Sensors

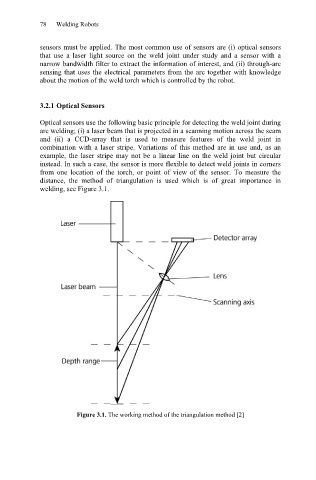

Optical sensors use the following basic principle for detecting the weld joint during

arc welding; (i) a laser beam that is projected in a scanning motion across the seam

and (ii) a CCD-array that is used to measure features of the weld joint in

combination with a laser stripe. Variations of this method are in use and, as an

example, the laser stripe may not be a linear line on the weld joint but circular

instead. In such a case, the sensor is more flexible to detect weld joints in corners

from one location of the torch, or point of view of the sensor. To measure the

distance, the method of triangulation is used which is of great importance in

welding, see Figure 3.1.

Figure 3.1. The working method of the triangulation method [2]