Page 96 - Welding Robots Technology, System Issues, and Applications

P. 96

Welding Robots

82

A laser-based seam tracker is typically mounted on the weld torch and has the weld

joint in its field of view some distance ahead in the weld path direction, see Figure

3.3. This means that the robot must use one degree of freedom to keep the sensor in

alignment with the weld joint during welding or, alternatively, use a separate

motion so that the sensor can rotate around the weld torch to maintain the

alignment relationship between the sensor and the weld torch. It should also be

noted that the seam tracking sensor must measure and deliver target positions of

the weld torch continuously and that these must be time stamped and stored in a

buffer for later use by the robot controller.

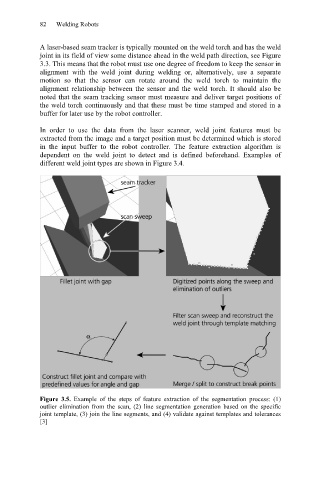

In order to use the data from the laser scanner, weld joint features must be

extracted from the image and a target position must be determined which is stored

in the input buffer to the robot controller. The feature extraction algorithm is

dependent on the weld joint to detect and is defined beforehand. Examples of

different weld joint types are shown in Figure 3.4.

Figure 3.5. Example of the steps of feature extraction of the segmentation process: (1)

outlier elimination from the scan, (2) line segmentation generation based on the specific

joint template, (3) join the line segments, and (4) validate against templates and tolerances

[3]