Page 100 - Welding Robots Technology, System Issues, and Applications

P. 100

Welding Robots

86

applied which are usually based on differential control and/or template matching of

the signal. If template matching is used together with continuous measurement of

the current, a more precise control can be made that can also take into account for

non-symmetric shapes of the joint profile.

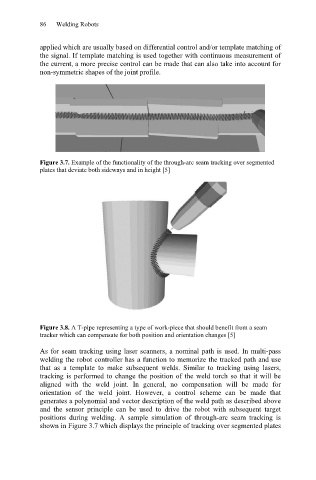

Figure 3.7. Example of the functionality of the through-arc seam tracking over segmented

plates that deviate both sideways and in height [5]

Figure 3.8. A T-pipe representing a type of work-piece that should benefit from a seam

tracker which can compensate for both position and orientation changes [5]

As for seam tracking using laser scanners, a nominal path is used. In multi-pass

welding the robot controller has a function to memorize the tracked path and use

that as a template to make subsequent welds. Similar to tracking using lasers,

tracking is performed to change the position of the weld torch so that it will be

aligned with the weld joint. In general, no compensation will be made for

orientation of the weld joint. However, a control scheme can be made that

generates a polynomial and vector description of the weld path as described above

and the sensor principle can be used to drive the robot with subsequent target

positions during welding. A sample simulation of through-arc seam tracking is

shown in Figure 3.7 which displays the principle of tracking over segmented plates