Page 95 - Welding Robots Technology, System Issues, and Applications

P. 95

81

Sensors for Welding Robots

lower wire feed speed (weld current), (iii) a too low current may however result in

a lack of fusion and cracking in the weld and to keep a higher current a weaving

motion of the welding torch can be applied to avoid the problem with burn-

through. This shows that the control scheme needs to consider many issues, of

which some are boundary conditions and some are counteracting each other,

leading to new ways to perform the weld operation.

In robotic welding of thicker plates, the welding is usually performed in several

passes, e.g. one root pass and additional passes to fill up the weld joint. In such

cases, the use of a tracking sensor can be applied in several ways. Normally,

tracking is applied for the root pass. During this operation the robot records the

weld path and subsequent passes can be overlaid with respect to the first path based

on the actual weld joint geometry.

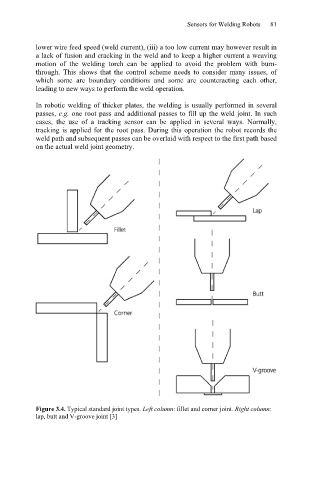

Figure 3.4. Typical standard joint types. Left column: fillet and corner joint. Right column:

lap, butt and V-groove joint [3]