Page 405 - Wind Energy Handbook

P. 405

BLADES 379

7.1.3 Practical modifications to optimum design

The result of the optimization described in the previous section is typically a blade

geometry in which both blade chord and blade twist vary approximately inversely

with radius, as illustrated in Figure 3.19. However, because the inboard section of

the blade makes only a small contribution to total power output (Figure 3.30), the

aerofoil section is generally not continued inboard of about 15 percent radius in

practice, and the chord at this radius is substantially reduced, to perhaps half the

theoretical optimum. It is then often found expedient to taper the chord uniformly

over the active length of the blade, with the tip chord and chord taper set so that the

chord distribution approximates closely to the optimum over the outboard half of

the blade (Figure 3.20).

The blade root area is normally circular in cross section in order to match up with

the pitch bearing in the case of pitchable blades, or to allow pitch angle adjustment at

the bolted flange (to compensate for non-standard air density) in the case of stall-

regulated blades. The transition from the root section to the aerofoil section outboard

of 15 percent radius should be a smooth one for structural reasons, with the result that

the latter section will have a high thickness to chord ratio of up to about 50 percent.

7.1.4 Form of blade structure

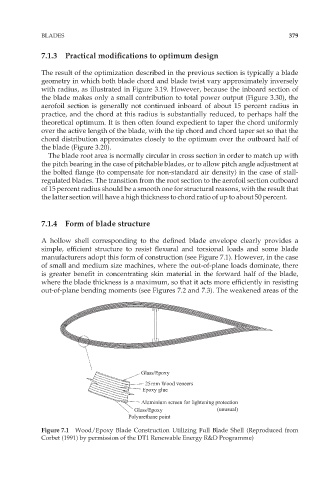

A hollow shell corresponding to the defined blade envelope clearly provides a

simple, efficient structure to resist flexural and torsional loads and some blade

manufacturers adopt this form of construction (see Figure 7.1). However, in the case

of small and medium size machines, where the out-of-plane loads dominate, there

is greater benefit in concentrating skin material in the forward half of the blade,

where the blade thickness is a maximum, so that it acts more efficiently in resisting

out-of-plane bending moments (see Figures 7.2 and 7.3). The weakened areas of the

Glass/Epoxy

25mm Wood veneers

Epoxy glue

Aluminium screen for lightening protection

Glass/Epoxy (unusual)

Polyurethane point

Figure 7.1 Wood/Epoxy Blade Construction Utilizing Full Blade Shell (Reproduced from

Corbet (1991) by permission of the DT1 Renewable Energy R&D Programme)