Page 406 - Wind Energy Handbook

P. 406

380 COMPONENT DESIGN

Filler

Glass/Epoxy web

Glass/Epoxy Glass/Epoxy

4mm Wood veneers Styrofoam

Epoxy glue Glass/Epoxy

Glass/Epoxy Gel coat

Gel coat

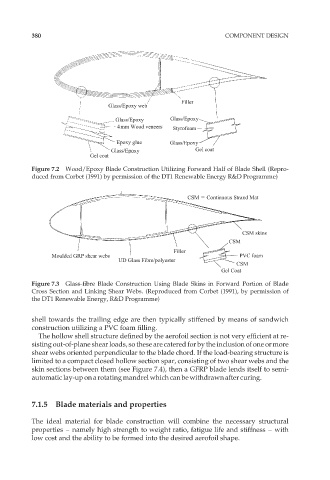

Figure 7.2 Wood/Epoxy Blade Construction Utilizing Forward Half of Blade Shell (Repro-

duced from Corbet (1991) by permission of the DT1 Renewable Energy R&D Programme)

CSM Continuous Strand Mat

CSM skins

CSM

Filler

Moulded GRP shear webs PVC foam

UD Glass Fibre/polyester

CSM

Gel Coat

Figure 7.3 Glass-fibre Blade Construction Using Blade Skins in Forward Portion of Blade

Cross Section and Linking Shear Webs. (Reproduced from Corbet (1991), by permission of

the DT1 Renewable Energy, R&D Programme)

shell towards the trailing edge are then typically stiffened by means of sandwich

construction utilizing a PVC foam filling.

The hollow shell structure defined by the aerofoil section is not very efficient at re-

sisting out-of-plane shear loads, so these are catered for by the inclusion of one or more

shear webs oriented perpendicular to the blade chord. If the load-bearing structure is

limited to a compact closed hollow section spar, consisting of two shear webs and the

skin sections between them (see Figure 7.4), then a GFRP blade lends itself to semi-

automatic lay-up on a rotatingmandrel which canbe withdrawn after curing.

7.1.5 Blade materials and properties

The ideal material for blade construction will combine the necessary structural

properties – namely high strength to weight ratio, fatigue life and stiffness – with

low cost and the ability to be formed into the desired aerofoil shape.