Page 407 - Wind Energy Handbook

P. 407

BLADES 381

CSM Continuous Strand Mat

CSM/polyester

Adhesive PVC foam

TFT wound spar

CSM/polyester

Gel coat

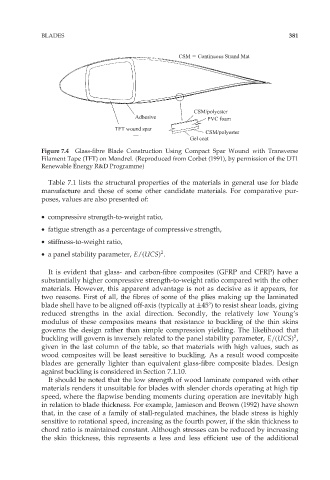

Figure 7.4 Glass-fibre Blade Construction Using Compact Spar Wound with Transverse

Filament Tape (TFT) on Mandrel. (Reproduced from Corbet (1991), by permission of the DT1

Renewable Energy R&D Programme)

Table 7.1 lists the structural properties of the materials in general use for blade

manufacture and those of some other candidate materials. For comparative pur-

poses, values are also presented of:

• compressive strength-to-weight ratio,

• fatigue strength as a percentage of compressive strength,

• stiffness-to-weight ratio,

2

• a panel stability parameter, E/(UCS) .

It is evident that glass- and carbon-fibre composites (GFRP and CFRP) have a

substantially higher compressive strength-to-weight ratio compared with the other

materials. However, this apparent advantage is not as decisive as it appears, for

two reasons. First of all, the fibres of some of the plies making up the laminated

blade shell have to be aligned off-axis (typically at 458) to resist shear loads, giving

reduced strengths in the axial direction. Secondly, the relatively low Young’s

modulus of these composites means that resistance to buckling of the thin skins

governs the design rather than simple compression yielding. The likelihood that

2

buckling will govern is inversely related to the panel stability parameter, E=(UCS) ,

given in the last column of the table, so that materials with high values, such as

wood composites will be least sensitive to buckling. As a result wood composite

blades are generally lighter than equivalent glass-fibre composite blades. Design

against buckling is considered in Section 7.1.10.

It should be noted that the low strength of wood laminate compared with other

materials renders it unsuitable for blades with slender chords operating at high tip

speed, where the flapwise bending moments during operation are inevitably high

in relation to blade thickness. For example, Jamieson and Brown (1992) have shown

that, in the case of a family of stall-regulated machines, the blade stress is highly

sensitive to rotational speed, increasing as the fourth power, if the skin thickness to

chord ratio is maintained constant. Although stresses can be reduced by increasing

the skin thickness, this represents a less and less efficient use of the additional