Page 409 - Wind Energy Handbook

P. 409

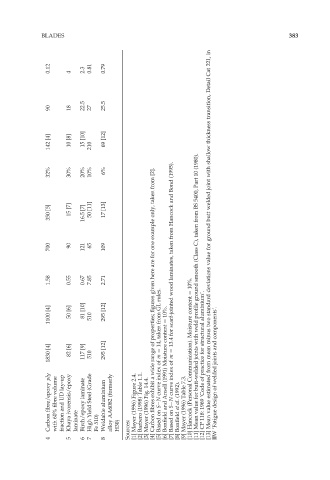

BLADES 383

in

221,

0.12 4 2.3 0.81 0.79 Cat

Detail

transition,

25.5

22.5

90 18 27

142 [4] [8] 10 [10] 15 210 [12] 69 thickness shallow

32% 30% 20% 10% 6% (1995). 5400, Part 10 (1980). with

taken from [2]. joint

scarf-jointed wood laminates, taken from Hancock and Bond

350 [5] 15 [7] 16.5 [7] 50 [11] 17 [13] only, welded butt

ground

700 90 121 65 109 for

value

1.58 0.55 0.67 7.85 2.71 content ¼ 10%. butt-welded joints with weld profile ground smooth (Class C), taken from BS deviations

14, taken from GL rules. for structural aluminium’. two components’.

1100 [4] 50 [6] 81 [10] 295 [12] a wide range of properties; figures given here are for one example standard

510

1830 [4] 82 [6] 117 [9] 510 295 [12] ¼ m Moisture content ¼ 10%. 13:4 ¼ m for minus mean

ply Steel (Grade (formerly S–N curve index of S–N curve index of (1992). [10] Hancock (Personal Communication). Moisture from estimated design of welded joints and

Carbon fibre/epoxy with 60% fibre volume fraction and UD lay-up ivorensis/epoxy laminate Birch/epoxy laminate High Yield Fe 510) Weldable aluminium alloy AA6082 [1] Mayer (1996) Figure 2.4. [2] Barbero (1998) Table 1.1. [3] Mayer (1996) Fig. 14.4. [4] Carbon fibres exhibit [6] Bonfield and Ansell (1991) et al. [9] Mayer (1996) Table 7.3. [11] Mean value for

4 Khaya 5 6 7 8 H30) Sources: [5] Based on [7] Based on [8] Bonfield [13] IIW ‘Fatigue