Page 416 - Wind Energy Handbook

P. 416

390 COMPONENT DESIGN

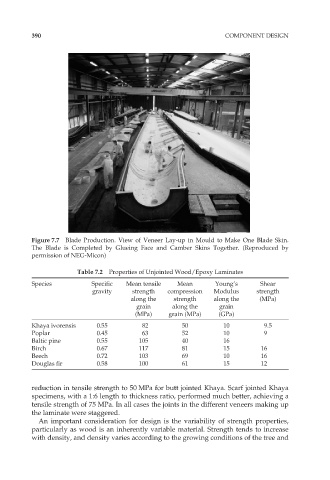

Figure 7.7 Blade Production. View of Veneer Lay-up in Mould to Make One Blade Skin.

The Blade is Completed by Glueing Face and Camber Skins Together. (Reproduced by

permission of NEG-Micon)

Table 7.2 Properties of Unjointed Wood/Epoxy Laminates

Species Specific Mean tensile Mean Young’s Shear

gravity strength compression Modulus strength

along the strength along the (MPa)

grain along the grain

(MPa) grain (MPa) (GPa)

Khaya ivorensis 0.55 82 50 10 9.5

Poplar 0.45 63 52 10 9

Baltic pine 0.55 105 40 16

Birch 0.67 117 81 15 16

Beech 0.72 103 69 10 16

Douglas fir 0.58 100 61 15 12

reduction in tensile strength to 50 MPa for butt jointed Khaya. Scarf jointed Khaya

specimens, with a 1:6 length to thickness ratio, performed much better, achieving a

tensile strength of 75 MPa. In all cases the joints in the different veneers making up

the laminate were staggered.

An important consideration for design is the variability of strength properties,

particularly as wood is an inherently variable material. Strength tends to increase

with density, and density varies according to the growing conditions of the tree and