Page 487 - Wind Energy Handbook

P. 487

TOWER 461

the extreme load, with the result that the bolts are not subject to fatigue loads.

Unfortunately, apart from the effect of splice plates on the external appearance,

there are practical difficulties of joint assembly, because bolting requires the

provision of some form of personnel access on the outside of the tower. Neverthe-

less splice plates are used on some towers.

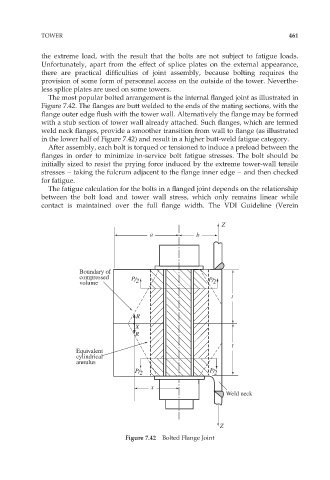

The most popular bolted arrangement is the internal flanged joint as illustrated in

Figure 7.42. The flanges are butt welded to the ends of the mating sections, with the

flange outer edge flush with the tower wall. Alternatively the flange may be formed

with a stub section of tower wall already attached. Such flanges, which are termed

weld neck flanges, provide a smoother transition from wall to flange (as illustrated

in the lower half of Figure 7.42) and result in a higher butt-weld fatigue category.

After assembly, each bolt is torqued or tensioned to induce a preload between the

flanges in order to minimize in-service bolt fatigue stresses. The bolt should be

initially sized to resist the prying force induced by the extreme tower-wall tensile

stresses – taking the fulcrum adjacent to the flange inner edge – and then checked

for fatigue.

The fatigue calculation for the bolts in a flanged joint depends on the relationship

between the bolt load and tower wall stress, which only remains linear while

contact is maintained over the full flange width. The VDI Guideline (Verein

Z

a b

Boundary of

compressed

volume P/ 2 P/ 2

t

R

X

R

t

Equivalent

cylindrical

annulus

P/ 2 P/ 2

x

Weld neck

Z

Figure 7.42 Bolted Flange Joint