Page 25 - Wire Bonding in Microelectronics

P. 25

4 Cha pte r O n e

1

2

Capillary

tool

3

Gold

wire

Spark US energy,

EFO pressure,

wand

and heat

to form ball

Chip

bond pad bond

4

5

Loop formation

Ball

bond

Package

bond pad

7

6

US energy, Crescent or

pressure, stitch bond

and heat

Package to form tail

bond pad bond

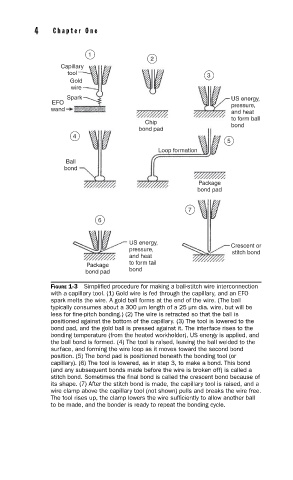

FIGURE 1-3 Simplifi ed procedure for making a ball-stitch wire interconnection

with a capillary tool. (1) Gold wire is fed through the capillary, and an EFO

spark melts the wire. A gold ball forms at the end of the wire. (The ball

typically consumes about a 300 µm length of a 25 µm dia. wire, but will be

less for fi ne-pitch bonding.) (2) The wire is retracted so that the ball is

positioned against the bottom of the capillary. (3) The tool is lowered to the

bond pad, and the gold ball is pressed against it. The interface rises to the

bonding temperature (from the heated workholder), US energy is applied, and

the ball bond is formed. (4) The tool is raised, leaving the ball welded to the

surface, and forming the wire loop as it moves toward the second bond

position. (5) The bond pad is positioned beneath the bonding tool (or

capillary). (6) The tool is lowered, as in step 3, to make a bond. This bond

(and any subsequent bonds made before the wire is broken off) is called a

stitch bond. Sometimes the fi nal bond is called the crescent bond because of

its shape. (7) After the stitch bond is made, the capillary tool is raised, and a

wire clamp above the capillary tool (not shown) pulls and breaks the wire free.

The tool rises up, the clamp lowers the wire suffi ciently to allow another ball

to be made, and the bonder is ready to repeat the bonding cycle.