Page 24 - Wire Bonding in Microelectronics

P. 24

The Technical Intr oduction to the Thir d Edition 3

Wedge 3

tool

1

2

Pressure

and

Wire

ultrasonic

energy

to form Bond

4

Loop

formation

Package

Pressure Wire

bond pad

and 6 clamp

ultrasonic 5

energy

to bond

Wire

Chip

break off

Package

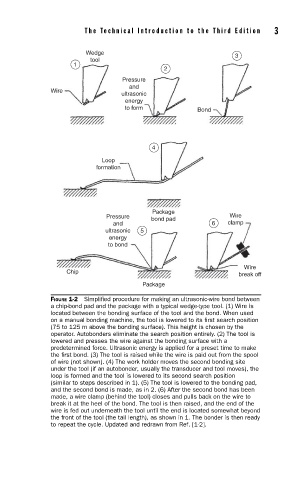

FIGURE 1-2 Simplifi ed procedure for making an ultrasonic-wire bond between

a chip-bond pad and the package with a typical wedge-type tool. (1) Wire is

located between the bonding surface of the tool and the bond. When used

on a manual bonding machine, the tool is lowered to its fi rst search position

(75 to 125 m above the bonding surface). This height is chosen by the

operator. Autobonders eliminate the search position entirely. (2) The tool is

lowered and presses the wire against the bonding surface with a

predetermined force. Ultrasonic energy is applied for a preset time to make

the fi rst bond. (3) The tool is raised while the wire is paid out from the spool

of wire (not shown). (4) The work holder moves the second bonding site

under the tool (if an autobonder, usually the transducer and tool moves), the

loop is formed and the tool is lowered to its second search position

(similar to steps described in 1). (5) The tool is lowered to the bonding pad,

and the second bond is made, as in 2. (6) After the second bond has been

made, a wire clamp (behind the tool) closes and pulls back on the wire to

break it at the heel of the bond. The tool is then raised, and the end of the

wire is fed out underneath the tool until the end is located somewhat beyond

the front of the tool (the tail length), as shown in 1. The bonder is then ready

to repeat the cycle. Updated and redrawn from Ref. [1-2].