Page 26 - Wire Bonding in Microelectronics

P. 26

The Technical Intr oduction to the Thir d Edition 5

Wedge

Wire

US

energy

Bond pad

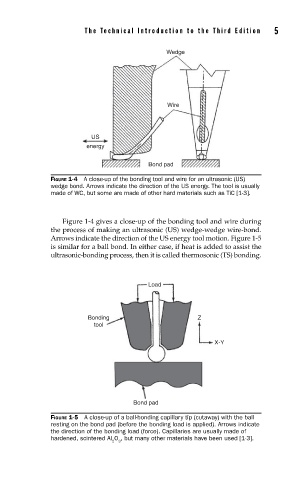

FIGURE 1-4 A close-up of the bonding tool and wire for an ultrasonic (US)

wedge bond. Arrows indicate the direction of the US energy. The tool is usually

made of WC, but some are made of other hard materials such as TiC [1-3].

Figure 1-4 gives a close-up of the bonding tool and wire during

the process of making an ultrasonic (US) wedge-wedge wire-bond.

Arrows indicate the direction of the US energy tool motion. Figure 1-5

is similar for a ball bond. In either case, if heat is added to assist the

ultrasonic-bonding process, then it is called thermosonic (TS) bonding.

Load

Bonding Z

tool

X-Y

Bond pad

FIGURE 1-5 A close-up of a ball-bonding capillary tip (cutaway) with the ball

resting on the bond pad (before the bonding load is applied). Arrows indicate

the direction of the bonding load (force). Capillaries are usually made of

hardened, scintered Al O , but many other materials have been used [1-3].

2 3