Page 79 - Wire Bonding in Microelectronics

P. 79

58 Cha pte r T h ree

22

20

18 Actual

Breaking strength (g) → 14 Composite

16

12

10

8

6

?

4

2

0

0 1 2 3 4 5 6

Elongation (%) →

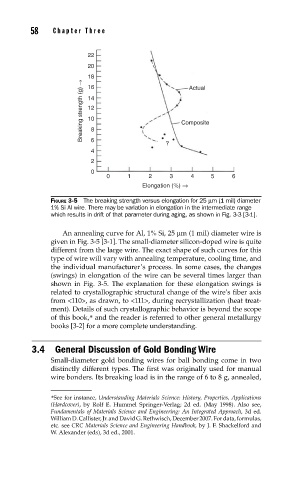

FIGURE 3-5 The breaking strength versus elongation for 25 µm (1 mil) diameter

1% Si Al wire. There may be variation in elongation in the intermediate range

which results in drift of that parameter during aging, as shown in Fig. 3-3 [3-1].

An annealing curve for Al, 1% Si, 25 µm (1 mil) diameter wire is

given in Fig. 3-5 [3-1]. The small-diameter silicon-doped wire is quite

different from the large wire. The exact shape of such curves for this

type of wire will vary with annealing temperature, cooling time, and

the individual manufacturer’s process. In some cases, the changes

(swings) in elongation of the wire can be several times larger than

shown in Fig. 3-5. The explanation for these elongation swings is

related to crystallographic structural change of the wire’s fiber axis

from <110>, as drawn, to <111>, during recrystallization (heat treat-

ment). Details of such crystallographic behavior is beyond the scope

of this book,∗ and the reader is referred to other general metallurgy

books [3-2] for a more complete understanding.

3.4 General Discussion of Gold Bonding Wire

Small-diameter gold bonding wires for ball bonding come in two

distinctly different types. The first was originally used for manual

wire bonders. Its breaking load is in the range of 6 to 8 g, annealed,

∗See for instance, Understanding Materials Science: History, Properties, Applications

(Hardcover), by Rolf E. Hummel Springer-Verlag; 2d ed. (May 1998). Also see,

Fundamentals of Materials Science and Engineering: An Integrated Approach, 3d ed.

William D. Callister, Jr. and David G. Rethwisch, December 2007. For data, formulas,

etc. see CRC Materials Science and Engineering Handbook, by J. F. Shackelford and

W. Alexander (eds), 3d ed., 2001.