Page 284 - Mechanical Behavior of Materials

P. 284

Section 7.4 Maximum Shear Stress Yield Criterion 285

σ

3

(a)

σ

2

σ = 0

3

axis

σ

1

σ

3

γ

axis (b)

β

α axis

α = β = γ

(σ , σ , σ ) D'

1 2 3

σ 1 D' S σ 2

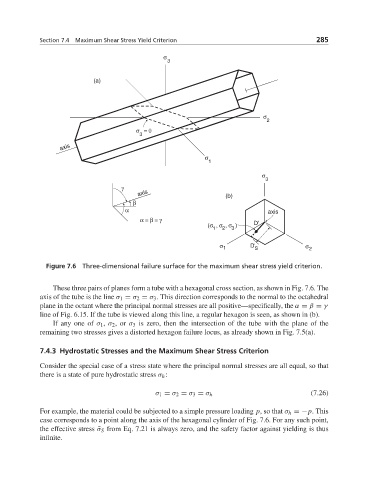

Figure 7.6 Three-dimensional failure surface for the maximum shear stress yield criterion.

These three pairs of planes form a tube with a hexagonal cross section, as shown in Fig. 7.6. The

axis of the tube is the line σ 1 = σ 2 = σ 3 . This direction corresponds to the normal to the octahedral

plane in the octant where the principal normal stresses are all positive—specifically, the α = β = γ

line of Fig. 6.15. If the tube is viewed along this line, a regular hexagon is seen, as shown in (b).

If any one of σ 1 , σ 2 ,or σ 3 is zero, then the intersection of the tube with the plane of the

remaining two stresses gives a distorted hexagon failure locus, as already shown in Fig. 7.5(a).

7.4.3 Hydrostatic Stresses and the Maximum Shear Stress Criterion

Consider the special case of a stress state where the principal normal stresses are all equal, so that

there is a state of pure hydrostatic stress σ h :

σ 1 = σ 2 = σ 3 = σ h (7.26)

For example, the material could be subjected to a simple pressure loading p, so that σ h =−p.This

case corresponds to a point along the axis of the hexagonal cylinder of Fig. 7.6. For any such point,

the effective stress ¯σ S from Eq. 7.21 is always zero, and the safety factor against yielding is thus

infinite.