Page 184 - Introduction to Marine Engineering

P. 184

170 Refrigeration, air conditioning and ventilation

inspection port tubjng

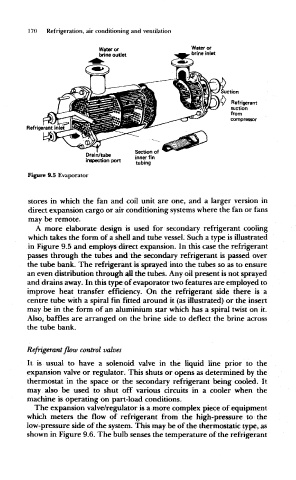

Figure 9.5 Evaporator

stores in which the fan and coil unit are one, and a larger version in

direct expansion cargo or air conditioning systems where the fan or fans

may be remote.

A more elaborate design is used for secondary refrigerant cooling

which takes the form of a shell and tube vessel. Such a type is illustrated

in Figure 9.5 and employs direct expansion. In this case the refrigerant

passes through the tubes and the secondary refrigerant is passed over

the tube bank. The refrigerant is sprayed into the tubes so as to ensure

an even distribution through all the tubes. Any oil present is not sprayed

and drains away. In this type of evaporator two features are employed to

improve heat transfer efficiency. On the refrigerant side there is a

centre tube with a spiral fin fitted around it (as illustrated) or the insert

may be in the form of an aluminium star which has a spiral twist on it.

Also, baffles are arranged on the brine side to deflect the brine across

the tube bank.

Refrigerant flow control valves

It is usual to have a solenoid valve in the liquid line prior to the

expansion valve or regulator. This shuts or opens as determined by the

thermostat in the space or the secondary refrigerant being cooled. It

may also be used to shut off various circuits in a cooler when the

machine is operating on part-load conditions.

The expansion valve/regulator is a more complex piece of equipment

which meters the flow of refrigerant from the high-pressure to the

low-pressure side of the system. This may be of the thermostatic type, as

shown in Figure 9.6. The bulb senses the temperature of the refrigerant