Page 125 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 125

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap10 Final Proof page 120 4.1.2007 8:26pm Compositor Name: SJoearun

10/120 EQUIPMENT DESIGN AND SELECTION

Figure 10.3 A typical horizontal double-tube separator (courtesy Petroleum Extension Services).

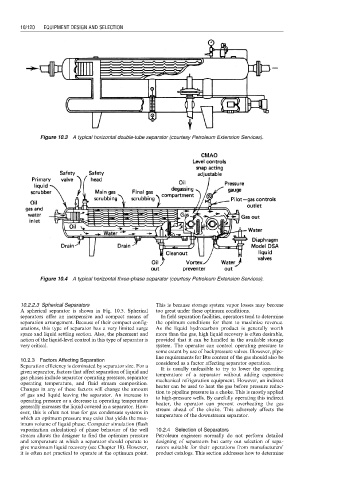

Figure 10.4 A typical horizontal three-phase separator (courtesy Petroleum Extension Services).

10.2.2.3 Spherical Separators This is because storage system vapor losses may become

A spherical separator is shown in Fig. 10.5. Spherical too great under these optimum conditions.

separators offer an inexpensive and compact means of In field separation facilities, operators tend to determine

separation arrangement. Because of their compact config- the optimum conditions for them to maximize revenue.

urations, this type of separator has a very limited surge As the liquid hydrocarbon product is generally worth

space and liquid settling section. Also, the placement and more than the gas, high liquid recovery is often desirable,

action of the liquid-level control in this type of separator is provided that it can be handled in the available storage

very critical. system. The operator can control operating pressure to

some extent by use of backpressure valves. However, pipe-

line requirements for Btu content of the gas should also be

10.2.3 Factors Affecting Separation

Separation efficiency is dominated by separator size. For a considered as a factor affecting separator operation.

given separator, factors that affect separation of liquid and It is usually unfeasible to try to lower the operating

gas phases include separator operating pressure, separator temperature of a separator without adding expensive

operating temperature, and fluid stream composition. mechanical refrigeration equipment. However, an indirect

Changes in any of these factors will change the amount heater can be used to heat the gas before pressure reduc-

of gas and liquid leaving the separator. An increase in tion to pipeline pressure in a choke. This is mostly applied

operating pressure or a decrease in operating temperature to high-pressure wells. By carefully operating this indirect

generally increases the liquid covered in a separator. How- heater, the operator can prevent overheating the gas

ever, this is often not true for gas condensate systems in stream ahead of the choke. This adversely affects the

which an optimum pressure may exist that yields the max- temperature of the downstream separator.

imum volume of liquid phase. Computer simulation (flash

vaporization calculation) of phase behavior of the well 10.2.4 Selection of Separators

stream allows the designer to find the optimum pressure Petroleum engineers normally do not perform detailed

and temperature at which a separator should operate to designing of separators but carry out selection of sepa-

give maximum liquid recovery (see Chapter 18). However, rators suitable for their operations from manufacturers’

it is often not practical to operate at the optimum point. product catalogs. This section addresses how to determine