Page 132 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 132

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap10 Final Proof page 127 4.1.2007 8:26pm Compositor Name: SJoearun

SEPARATION SYSTEMS 10/127

. Space adsorbents degenerate with use and require effective of the glycols because of its superior dew-point

replacement depression, operating cost, and operation reliability. TEG

has been successfully used to dehydrate sweet and sour

Dehydrating tower must be regenerated and cooled for natural gases over wide ranges of operating conditions.

operation before another tower approaches exhaustion. Dew-point depression of 40–1408F can be achieved at a

The maximum allowable time on dehydration gradually gas pressure ranging from 25 to 2,500 psig and gas tem-

shortens because desiccant loses capacity with use. perature between 40 and 1608F. The dew-point depression

Although this type of dehydrator has high adaptability

to sudden load changes, sudden pressure surges should be obtained depends on the equilibrium dew-point tempera-

avoided because they may upset the desiccant bed and ture for a given TEG concentration and contact tempera-

channel the gas stream resulting in poor dehydration. If a ture. Increased glycol viscosity may cause problems at lower

plant is operated above its rated capacity, high-pressure contact temperature. Thus, heating of the natural gas may

loss may introduce some attrition to occur. Attrition be desirable. Very hot gas streams are often cooled before

causes fines, which may in turn cause excessive pressure dehydration to prevent vaporization of TEG.

loss and result in loss of capacity. The feeding-in gas must be cleaned to remove all liquid

Replacing the desiccant should be scheduled and com- water and hydrocarbons, wax, sand, drilling muds, and

pleted ahead of the operating season. To maintain con- other impurities. These substances can cause severe foam-

tinuous operation, this may require discarding the ing, flooding, higher glycol losses, poor efficiency, and

desiccant before its normal operating life is reached. To increased maintenance in the dehydration tower or ab-

cut operating costs, the inlet part of the tower can be sorber. These impurities can be removed using an efficient

recharged and the remainder of the desiccant retained scrubber, separator, or even a filter separator for very

because it may still possess some useful life. Additional contaminated gases. Methanol, injected at the wellhead

as hydrate inhibitor, can cause several problems for glycol

service life of the desiccant may be obtained if the direction dehydration plants. It increases the heat requirements of

of gas flow is reversed at a time when the tower would the glycol regeneration system. Slugs of liquid methanol

normally be recharged.

can cause flooding in the absorber. Methanol vapor vented

to the atmosphere with the water vapor from the regener-

10.3.2.3 Dehydration by Absorption ation system is hazardous and should be recovered or

Water vapor is removed from the gas by intimate contact vented at nonhazardous concentrations.

with a hygroscopic liquid desiccant in absorption dehydra-

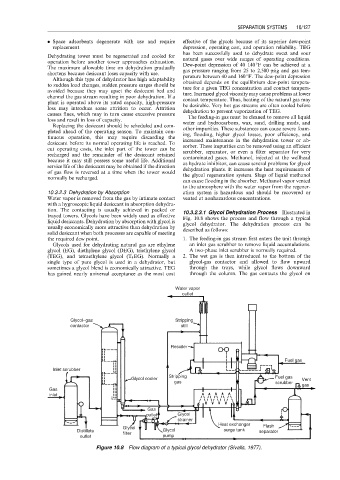

tion. The contacting is usually achieved in packed or 10.3.2.3.1 Glycol Dehydration Process Illustrated in

trayed towers. Glycols have been widely used as effective Fig. 10.8 shows the process and flow through a typical

liquid desiccants. Dehydration by absorption with glycol is glycol dehydrator. The dehydration process can be

usually economically more attractive than dehydration by described as follows:

solid desiccant when both processes are capable of meeting

the required dew point. 1. The feeding-in gas stream first enters the unit through

Glycols used for dehydrating natural gas are ethylene an inlet gas scrubber to remove liquid accumulations.

glycol (EG), diethylene glycol (DEG), triethylene glycol A two-phase inlet scrubber is normally required.

(TEG), and tetraethylene glycol (T 4 EG). Normally a 2. The wet gas is then introduced to the bottom of the

single type of pure glycol is used in a dehydrator, but glycol-gas contactor and allowed to flow upward

sometimes a glycol blend is economically attractive. TEG through the trays, while glycol flows downward

has gained nearly universal acceptance as the most cost through the column. The gas contacts the glycol on

Water vapor

outlet

Glycol−gas Stripping

contactor still

Resoiler

Fuel gas

Inlet scrubber

Stripping Fuel gas

Glycol cooler Vent

gas scrubber

gas

Gas

inlet

Gas

outlet Glycol

strainer

Heat exchanger

Glycol Flash

Distillate Glycol surge tank separator

filter

outlet pump

Figure 10.8 Flow diagram of a typical glycol dehydrator (Sivalls, 1977).