Page 131 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 131

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap10 Final Proof page 126 4.1.2007 8:26pm Compositor Name: SJoearun

10/126 EQUIPMENT DESIGN AND SELECTION

not result in sufficiently low water contents to permit contaminants in the gas. The filtered gas flows downward

injection into a pipeline. Further dehydration by absorp- during dehydration through one adsorber containing a

tion or adsorption is often required. desiccant bed. The down-flow arrangement reduces dis-

turbance of the bed caused by the high gas velocity during

the adsorption. While one adsorber is dehydrating, the

10.3.2.1 Dehydration by Cooling other adsorber is being regenerated by a hot stream of

The ability of natural gas to contain water vapor decreases inlet gas from the regeneration gas heater. A direct-fired

as the temperature is lowered at constant pressure. During heater, hot oil, steam, or an indirect heater can supply the

the cooling process, the excess water in the vapor state necessary regeneration heat. The regeneration gas usually

becomes liquid and is removed from the system. Natural flows upward through the bed to ensure thorough regen-

gas containing less water vapor at low temperature is output eration of the bottom of the bed, which is the last area

from the cooling unit. The gas dehydrated by cooling is still contacted by the gas being dehydrated. The hot regener-

at its water dew point unless the temperature is raised again ated bed is cooled by shutting off or bypassing the heater.

or the pressure is decreased. Cooling for the purpose of gas The cooling gas then flows downward through the bed so

dehydration is sometimes economical if the gas temperature that any water adsorbed from the cooling gas will be at the

is unusually high. It is often a good practice that cooling is top of the bed and will not be desorbed into the gas during

used in conjunction with other dehydration processes. the dehydration step. The still-hot regeneration gas and

Gas compressors can be used partially as dehydrators. the cooling gas flow through the regeneration gas cooler to

Because the saturation water content of gases decreases at condense the desorbed water. Power-operated valves acti-

higher pressure, some water is condensed and removed vated by a timing device switch the adsorbers between the

from gas at compressor stations by the compressor dis- dehydration, regeneration, and cooling steps.

charge coolers. Modern lean oil absorption gas plants use Under normal operating conditions, the usable life of a

mechanical refrigeration to chill the inlet gas stream. desiccant ranges from 1 to 4 years. Solid desiccants become

Ethylene glycol is usually injected into the gas chilling less effective in normal use because of loss of effective

section of the plant, which simultaneously dehydrates the surface area as they age. Abnormally fast degradation

gas and recovers liquid hydrocarbons, in a manner similar occurs through blockage of the small pores and capillary

to the low-temperature separators. openings lubricating oils, amines, glycols, corrosion inhibi-

tors, and other contaminants, which cannot be removed

during the regeneration cycle. Hydrogen sulfide can also

10.3.2.2 Dehydration by Adsorption damage the desiccant and reduce its capacity.

‘‘Adsorption’’ is defined as the ability of a substance to The advantages of solid-desiccant dehydration include

hold gases or liquids on its surface. In adsorption dehy- the following:

dration, the water vapor from the gas is concentrated and

held at the surface of the solid desiccant by forces caused

by residual valiancy. Solid desiccants have very large sur- . Lower dew point, essentially dry gas (water content

face areas per unit weight to take advantage of these <1.0 lb/MMcf) can be produced

surface forces. The most common solid adsorbents used . Higher contact temperatures can be tolerated with some

today are silica, alumina, and certain silicates known as adsorbents

molecular sieves. Dehydration plants can remove practic- . Higher tolerance to sudden load changes, especially on

ally all water from natural gas using solid desiccants. startup

Because of their great drying ability, solid desiccants are . Quick start up after a shutdown

employed where higher efficiencies are required. . High adaptability for recovery of certain liquid hydro-

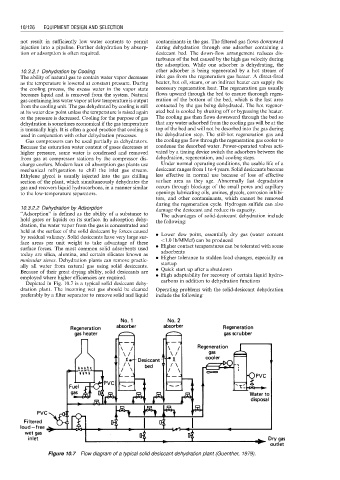

Depicted in Fig. 10.7 is a typical solid desiccant dehy- carbons in addition to dehydration functions

dration plant. The incoming wet gas should be cleaned Operating problems with the solid-desiccant dehydration

preferably by a filter separator to remove solid and liquid include the following:

Figure 10.7 Flow diagram of a typical solid desiccant dehydration plant (Guenther, 1979).