Page 198 - Petroleum Production Engineering, A Computer-Assisted Approach

P. 198

Guo, Boyun / Computer Assited Petroleum Production Engg 0750682701_chap13 Final Proof page 194 3.1.2007 9:07pm Compositor Name: SJoearun

13/194 ARTIFICIAL LIFT METHODS

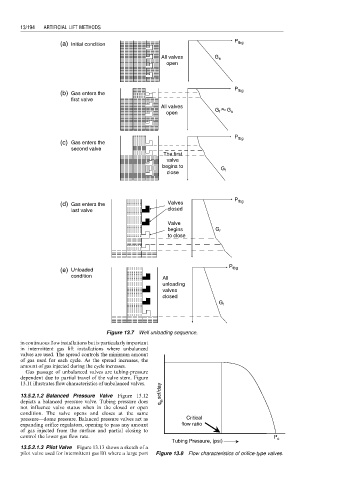

P

(a) Initial condition tbg

All valves G s

open

P tbg

(b) Gas enters the

first valve

All valves

open G f G s

P tbg

(c) Gas enters the

second valve

The first

valve

begins to

G

close f

(d) Gas enters the Valves P tbg

last valve closed

Valve

begins G f

to close

P tbg

(e) Unloaded

condition

All

unloading

valves

closed

G f

Figure 13.7 Well unloading sequence.

in continuous flow installations but is particularly important

in intermittent gas lift installations where unbalanced

valves are used. The spread controls the minimum amount

of gas used for each cycle. As the spread increases, the

amount of gas injected during the cycle increases.

Gas passage of unbalanced valves are tubing-pressure

dependent due to partial travel of the valve stem. Figure

13.11 illustrates flow characteristics of unbalanced valves.

q g, scf/day

13.5.2.1.2 Balanced Pressure Valve Figure 13.12

depicts a balanced pressure valve. Tubing pressure does

not influence valve status when in the closed or open

condition. The valve opens and closes at the same

pressure—dome pressure. Balanced pressure valves act as Critical

expanding orifice regulators, opening to pass any amount flow ratio

of gas injected from the surface and partial closing to

control the lower gas flow rate. P

Tubing Pressure, (psi) c

13.5.2.1.3 Pilot Valve Figure 13.13 shows a sketch of a

pilot valve used for intermittent gas lift where a large port Figure 13.8 Flow characteristics of orifice-type valves.